PRODUCT PARAMETERS

Description

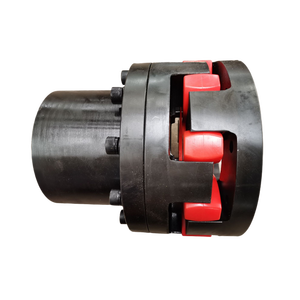

Introduction to Mining Carbon Steel Forging Double Helical Large Gear Shaft

Mining Carbon Steel Forging Double Helical Large Gear Shaft are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Mining Carbon Steel Forging Double Helical Large Gear Shaft

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Mining Carbon Steel Forging Double Helical Large Gear Shaft)

Specification of Mining Carbon Steel Forging Double Helical Large Gear Shaft

Introduction

Mining carbon steel forging double helical large gear shaft is a high-quality and durable product that is widely used in various industries for manufacturing rotating machinery. The manufacturing process involves heating the carbon steel to a required temperature, forging it using dies, and then tempering it to improve its strength and reduce its deformation. This article will provide an overview of the specification of mining carbon steel forging double helical large gear shaft.

Material Selection

The material selection plays a crucial role in determining the quality and durability of the final product. Mining carbon steel is commonly used due to its excellent tensile strength, heat resistance, and corrosion resistance. The choice of the type of forging operation, such as single or double helical, can also affect the final product’s performance. A double helical forging operation results in a smoother and more uniform finish compared to a single helical forging operation.

Die Design

Die design is another critical factor in ensuring the quality and reliability of the mining carbon steel forging double helical large gear shaft. The die shape and size must be designed according to the specific requirements of the final product. A properly designed die can help to produce accurate and precise forged parts with minimal defects. Additionally, the die must be designed with sufficient heat transfer to ensure that the forging process is carried out efficiently without overheating or cracking.

Tempers

Tempering is an essential step in converting the carbon steel into a hardened anded state. The tempering process helps to improve the product’s mechanical properties, including its hardness, strength, and wear resistance. The process involves heating the forging material to a higher temperature than at which it would normally melt, then slowly cooling it until it reaches a desirable temperature.

Testing and Certification

Before the mining carbon steel forging double helical large gear shaft can be sold, it must undergo rigorous testing and certification to ensure its quality and compliance with industry standards. This testing includes physical tests, such as the tensile strength and hardness of the forged parts, as well as non-destructive testing, such as visual inspection and measurements of internal dimensions.

Conclusion

Mining carbon steel forging double helical large gear shaft is a reliable and high-quality product that is suitable for a wide range of applications. By carefully selecting the right materials, designing the proper die, tempering appropriately, and undergoing thorough testing and certification, manufacturers can produce forged parts that meet their specific requirements and perform reliably over time.

(Mining Carbon Steel Forging Double Helical Large Gear Shaft)

Applications of Mining Carbon Steel Forging Double Helical Large Gear Shaft

Carbon steel forging is a popular process used to produce high-quality, durable gears for use in various applications. One particularly promising application of carbon steel forging is for the manufacture of double helical large gear shafts.

Double helix gears are known for their excellent performance and durability, making them ideal for use in applications that require precise motion and heavy loads. The unique shape of the gears allows them to carry more torque and rotate at higher speeds than traditional single helix gears, resulting in improved efficiency and reduced wear on moving parts.

To utilize this technology, carbon steel forging companies can produce double helical large gear shafts using specialized equipment and techniques. These processes typically involve melting steel to create a stock and then forging it into the desired shape using multiple stages of heat treatment and shaping.

The resulting double helical large gear shafts are characterized by their strong and durable construction, as well as their ability to resist corrosion and wear. They are commonly used in industries such as automotive, aerospace, and power generation, where precision movement and heavy loads are critical factors.

In conclusion, carbon steel forging has emerged as a promising technology for producing high-quality, durable gears for use in various applications. By utilizing advanced techniques and specialized equipment, companies can produce double helical large gear shafts that are suitable for a wide range of industries and applications.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Mining Carbon Steel Forging Double Helical Large Gear Shaft

1. What is carbon steel forging?

Carbon steel forging is a process in which steel bars are heat treated to produce a harder and stronger metal by melting them at high temperatures and then allowing them to cool slowly. This results in the formation of strong, durable gears with a wide range of applications.

2. What are the benefits of using carbon steel forging double helical large gear shafts?

Carbon steel forging provides several benefits over traditional manufacturing methods. Firstly, it is more durable and less prone to wear and tear, making it ideal for long-term use in demanding applications such as mining and construction equipment. Secondly, it allows for precise control over the size and shape of the gears, resulting in better performance and reduced maintenance requirements. Finally, the process can be performed on a variety of materials, including carbon steel, aluminum, and titanium, providing flexibility in choosing the best material for specific applications.

3. How does carbon steel forging work?

The process begins with melting a stock of steel bars into a molten state. Once the steel has cooled, it is separated from the melt, leaving behind a solid block of steel. This solid block is then cut into individual bars, which are then combined to form larger gears.

4. What is the temperature required for carbon steel forging?

The temperature required for carbon steel forging depends on the desired strength and durability of the final product. Generally speaking, the higher the temperature, the softer the steel will become, which can result in lower quality gears. However, the process can be controlled to produce gears that meet both strength and durability requirements.

5. Are there any environmental concerns associated with carbon steel forging?

Yes, there are some environmental concerns associated with carbon steel forging. One potential issue is the emissions of carbon dioxide during the process, which can contribute to climate change if not managed properly. To mitigate these concerns, manufacturers may use energy-efficient processes or adopt more sustainable sourcing practices. Additionally, the process can generate hazardous waste, so proper disposal and recycling procedures must be followed.

(Mining Carbon Steel Forging Double Helical Large Gear Shaft)

REQUEST A QUOTE

RELATED PRODUCTS

Kalmar Planetary Gear Box Shaft Model 923349.0589/923349.0305 for Material Handling Equipment Parts

Shaft and Wheel TF08L 1100-016-105 / 1100-016-105 49134-00020 9 blades k18

Luoyang Wangli custom large gear shaft Mining machinery parts Large module gear shaft

Customized Professional Forging Steel Crankshaft Professional Machining Services for Engine Crankshaft

RU8509 baler arm shaft bearing flat seal drum seal maintenance free high-quality agricultural machinery bearings