PRODUCT PARAMETERS

Description

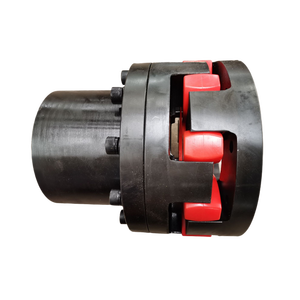

Introduction to Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining

Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining)

Specification of Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining

In the field of machine tool engineering, shaft machining is a critical process that involves turning metal components such as shafts and sleeves into their final shape and size. The specific specifications for shaft machining can vary depending on the type of material being processed, the desired dimensionality, and other requirements.

One of the key factors in specifying shaft machining specifications is determining the material to be used. Common materials used for shaft machining include steel, aluminum, titanium, and bronze. Each material has its own strengths and weaknesses, which must be considered when selecting the appropriate material for a particular application.

Another important factor in specifying shaft machining specifications is determining the length and diameter of the shaft being machined. This information should be provided by the manufacturer or supplier of the machine tool used, along with any other relevant dimensions such as thread pitch and bore size.

The depth and width of the axis of rotation in a machine shop also play an important role in shaft machining specifications. The depth of the axis determines the amount of space available for the cutting tool to move around the axis, while the width of the axis determines the maximum cutting force that can be applied to the tool.

When it comes to mass production fabrication, shaft machining specifications may be even more complex than those for individual parts. In these cases, specialized machinery such as CNC mills and lathes may be required to produce high volumes of precision parts efficiently and consistently.

Custom-made precision parts machining is another option for individuals or businesses that require high-quality, custom-made components that meet specific specifications. This can include anything from prototypes to production runs of thousands of parts.

Overall, specifying hardware processing shaft machining specifications requires careful consideration of the material to be used, the length and diameter of the shaft being machined, and the depth and width of the axis of rotation. Additionally, knowledge of mass production fabrication techniques and the ability to customize precision parts machining can help ensure that the final product meets the necessary specifications and performs well over time.

(Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining)

Applications of Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining

shaft machining is a process that involves turning metal shafts into precise and functional parts. This process is commonly used in industries such as aerospace, automotive, and medical devices to manufacture high-quality parts with minimal waste.

One of the key benefits of using hardware processing shaft machining is its ability to produce complex shapes and geometries with high precision. Machining can be used to create intricate designs that would be difficult or impossible to produce by hand, such as bolts and nuts, skewers, and surgical instruments.

In addition to producing high-quality parts, hardware processing shaft machining also has significant advantages over traditional manufacturing methods. For example, it is typically faster and more efficient than other processes due to the use of automated machinery and computer-controlled tools. This means that manufacturers can produce larger quantities of parts at a lower cost, making it an attractive option for many companies.

Another advantage of hardware processing shaft machining is its ability to produce parts in large quantities on a consistent basis. By automating the process, manufacturers can quickly and easily produce parts on demand, which can save time and reduce costs associated with inventory management.

Finally, hardware processing shaft machining can provide greater customization options for customers. Companies can work closely with manufacturers to design and fabricate parts to meet specific customer requirements, such as unique features or tolerances.

Overall, hardware processing shaft machining is a powerful tool for manufacturers looking to produce high-quality parts with minimal waste. Its ability to produce complex shapes and geometries with high precision, speed, efficiency, and customization options make it an attractive option for a wide range of industries.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining

1. What is shaft machining?

– shaft machining is a process that involves turning aluminum or other materials into shafts for use in various industries, such as aerospace and automotive.

2. How does shaft machining work?

– During shaft machining, a lathe machine is used to remove the material from the metal while keeping the shape and size of the shaft accurately controlled.

3. Can shaft machining be done on any type of metal?

– No, only metals like aluminum, titanium, steel, and iron can be machined using shaft machining techniques.

4. Are there different types of shaft machining processes available?

– Yes, there are several types of shaft machining processes, including: coolant-driven milling, hydrostatic milling, and coolant-assisted lapping.

5. What is mass production fabrication?

– Mass production fabrication is a manufacturing method that involves producing large quantities of identical products at once through automation and computer control.

6. How does mass production fabrication differ from custom made precision parts machining?

– Mass production fabrication is typically faster and more cost-effective than custom made precision parts machining, but it may not be suitable for highly detailed or complex parts. Custom made precision parts machining is often necessary for parts with intricate geometries and tight tolerances.

7. Is CNC service available for shaft machining?

– Yes, CNC (Computer Numerical Control) services are available for shaft machining, allowing for precise measurements and automated execution of complex operations.

8. Can I receive custom made precision parts machining?

– Yes, customers can request custom made precision parts machining based on their specific needs and requirements. Our team will work closely with you to ensure that your parts meet all necessary specifications and standards.

9. Are there any limitations to the materials that can be machined using shaft machining?

– While most metals can be machined using shaft machining techniques, some materials like diamond or ceramic may have limitations on the size and shape of the part that can be produced. Our team will carefully consider these factors when recommending suitable materials for your project.

10. How do I get started with CNC service for shaft machining?

– To get started with CNC service for shaft machining, please contact us to discuss your specific needs and provide details about the materials you want to machine. Our team will then provide you with a quote and help guide you through the process of scheduling an appointment with one of our experts.

(Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining)

REQUEST A QUOTE

RELATED PRODUCTS

linear ball spline SLT013 SLT016 SLT020 spline shaft with nut

Comprehensive Production All Types Of Shafts Precisely Engineered Alloy Aluminum Stainless Steel Long Linear Shafts Suitable

High-strength Ship Propeller Shaft Alloy Ring Forgings 1.4418/X4CrNiMo16-5-1

Custom Round shaft Precision 304 Stainless Steel Long Sus shafts

201 303 430 317 329 347 630 416 410 420 904l 316l 310s 2507 Round Stainless Steel Shaft 316 304 Stainless Steel Bar Rod