PRODUCT PARAMETERS

Description

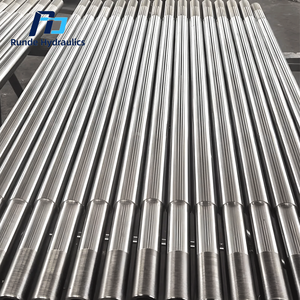

Introduction to Quality Guarantee Aluminum shaft customization Aluminum shaft processing small shaft processing

Quality Guarantee Aluminum shaft customization Aluminum shaft processing small shaft processing are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Quality Guarantee Aluminum shaft customization Aluminum shaft processing small shaft processing

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Quality Guarantee Aluminum shaft customization Aluminum shaft processing small shaft processing)

Specification of Quality Guarantee Aluminum shaft customization Aluminum shaft processing small shaft processing

Aluminum shaft customization is an important aspect of quality control in manufacturing processes. It involves modifying the dimensions, shape, and finish of aluminum shafts to meet specific customer requirements.

One common customization option for aluminum shafts is the ability to make them longer or shorter than their original length. This can be useful if the desired length cannot be achieved through standard design or production methods. Additionally, aluminum shafts can be customized in terms of their diameter, material type (such as stainless steel or titanium), and finishing options (such as chrome plating or anodizing).

。、,。

。,。,、()()。

Overall, aluminum shaft customization is an essential part of quality control in the manufacturing process. By making these modifications to improve the performance and durability of aluminum shafts, manufacturers can enhance their products and differentiate themselves from competitors.

(Quality Guarantee Aluminum shaft customization Aluminum shaft processing small shaft processing)

Applications of Quality Guarantee Aluminum shaft customization Aluminum shaft processing small shaft processing

Aluminum shafts are versatile and widely used in various industries due to their lightweight, high strength, and corrosion resistance. One important application of aluminum shafts is in the manufacturing of customized products.

Customization refers to the process of modifying or personalizing a product based on customer specifications. This can include changing the shape, size, material, finish, or other features of the product. For example, a manufacturer may choose to customize an aluminum shaft for a specific application, such as a food processing machine or a heavy machinery tool.

In this case, the aluminum shaft is customized to meet the specific requirements of the customer’s needs. The customization process typically involves several steps:

1. Needs analysis: The manufacturer first analyzes the customer’s needs to determine what type of aluminum shaft is required and what features it should have.

2. Design drawing: Based on the needs analysis, the manufacturer creates a design drawing that outlines the desired aluminum shaft configuration and shape.

3. Material selection: The manufacturer selects the appropriate aluminum alloy based on factors such as strength, weight, and cost-effectiveness.

4. Machining and assembly: The aluminum shaft is machined to the exact dimensions specified in the design drawing using specialized equipment and techniques. Then, it is assembled with precision and care to ensure that all components fit together properly.

5. Testing and inspection: Once the aluminum shaft has been completed, it is tested and inspected to ensure that it meets all quality standards.

In conclusion, aluminum shaft customization is an important process that allows manufacturers to create personalized products that meet the unique needs of their customers. By carefully designing, selecting, and customizing aluminum shafts, manufacturers can increase productivity, reduce costs, and improve customer satisfaction.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Quality Guarantee Aluminum shaft customization Aluminum shaft processing small shaft processing

1. What is the difference between aluminum shaft customization and small shaft processing?

* Aluminum shaft customization involves modifying the shape or size of an existing aluminum shaft to meet specific requirements, such as customizing the shaft for a particular application or improving its strength.

* Small shaft processing, on the other hand, involves creating new aluminum shafts from scratch by melting down raw materials and shaping them into the desired shape.

2. Is it possible to customize aluminum shafts without prior experience in this process?

* While not everyone may be familiar with aluminum shaft customization, it is possible to learn this skill through training and guidance from experienced professionals.

* Many companies offer training programs or hire experienced professionals who can guide clients through the process of designing and producing customized aluminum shafts.

3. How long does it typically take to complete aluminum shaft customization?

* The time required for aluminum shaft customization can vary depending on several factors, including the complexity of the design, the number of prototypes required, and the quality control measures implemented during production.

* In general, however, most aluminum shaft customization projects can be completed within a few weeks or months, although longer periods of time may be needed if there are complex designs or require extensive testing.

4. Can aluminum shaft customization be done for customized equipment or machinery?

* Yes, aluminum shaft customization can be used for customized equipment or machinery, including servers, computers, printers, and other electronic devices.

* Customized aluminum shafts can be tailored to meet the specific needs of each individual piece of equipment, resulting in increased performance and efficiency.

5. Are aluminum shaft customization costs generally higher than the cost of standard aluminum parts?

* Yes, aluminum shaft customization often requires additional resources, including specialized tools and equipment, specialized training, and specialized expertise, which can result in higher costs compared to standard aluminum parts.

* However, the benefits of custom aluminum shafts can also outweigh the costs, particularly when the cost savings outweigh the additional investment required for customization.

(Quality Guarantee Aluminum shaft customization Aluminum shaft processing small shaft processing)

REQUEST A QUOTE

RELATED PRODUCTS

SDS Drive Shafts 2201010W02 CS35 1.6L 5MT Left Half Shaft For Changan

Professional Direct ing Practical Stainless Rod Steel Shaft Round Rod Bar Astm304 Sus304

316 304 stainless steel rod long 2mm 8mm aluminum shaft pin 25mm 40mm threaded knurled shaft steel metal shaft

Whole High Quality Mtz Belarus Tractor Spare Parts Oem 112-2203010 Cardan Shaft

High-strength Ship Propeller Shaft Alloy Ring Forgings 1.4418/X4CrNiMo16-5-1