PRODUCT PARAMETERS

Description

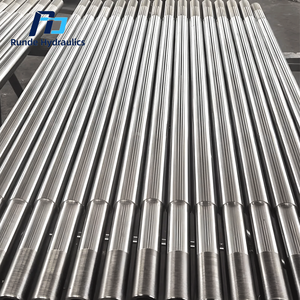

Introduction to Stainless steel CNC lathe machining milling customized non-standard parts high-precision machining Threaded Step Eccentric Shaft

Stainless steel CNC lathe machining milling customized non-standard parts high-precision machining Threaded Step Eccentric Shaft are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Stainless steel CNC lathe machining milling customized non-standard parts high-precision machining Threaded Step Eccentric Shaft

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Stainless steel CNC lathe machining milling customized non-standard parts high-precision machining Threaded Step Eccentric Shaft)

Specification of Stainless steel CNC lathe machining milling customized non-standard parts high-precision machining Threaded Step Eccentric Shaft

Stainless Steel CNC Lathe Machining: A High- Precision Tool for Customized Non-Standard Parts

In today’s world, the demand for custom-designed and specialized products is increasing rapidly due to the complexity of modern manufacturing processes. One such process that demands precision and consistency is CNC (Computer Numerical Control) lathem。A widely used tool for this purpose is the stainless steel CNC lathe machine.

The CNC lathe machine provides highly precise machining capabilities by utilizing advanced control systems, automated machinery, and computer-aided design (CAD) software. The machine can handle complex geometries with ease, making it an ideal choice for turning non-standard parts or customizing existing designs. The ability to machine from various angles and in multiple directions ensures accurate positioning and alignment of components.

Moreover, the use of stainless steel materials offers excellent wear resistance and durability, ensuring that even after long-term usage, the machine will continue to function smoothly and efficiently. The machine’s extensive tool selection allows for the customization of each part to meet specific requirements, reducing waste and minimizing production time.

Another advantage of using the CNC lathe machine is its versatility. It can be utilized for a wide range of tasks, including turning, boring, drilling, threading, and more. This flexibility makes it an invaluable tool for manufacturers looking to produce large quantities of high-quality custom parts quickly and cost-effectively.

In conclusion, the stainless steel CNC lathe machine is a highly versatile tool that offers superior precision and accuracy for the customization of non-standard parts. Its unique combination of advanced technology, reliability, and versatility make it a must-have for any manufacturer seeking to stay ahead in their industry.

(Stainless steel CNC lathe machining milling customized non-standard parts high-precision machining Threaded Step Eccentric Shaft)

Applications of Stainless steel CNC lathe machining milling customized non-standard parts high-precision machining Threaded Step Eccentric Shaft

Stainless Steel CNC Lathes Machining Milling Customized Non-Standard Parts High-precision Machining Threaded Step Eccentric Shaft is an innovative toolset that offers the capability to manufacture complex and customized parts with unparalleled precision and efficiency. The product consists of a series of CNC lathes, milling machines, and threaders that can be used for various applications.

The CNC lathes are equipped with advanced control systems that allow for precise manipulation of materials. They can be programmed to perform a wide range of operations, including drilling, milling, and chiseling, which can be tailored to meet specific requirements.

The milling machines are capable of producing detailed patterns on a variety of surfaces, including metals, plastics, and composites. They use powerful motors and variable speeds to achieve high-precision milling results.

Threaded step eccentric shafts are a critical component in many applications where stability and accuracy are essential. These shafts are made from durable stainless steel and are designed to resist wear and tear over time. They have a unique feature called “threading,” which allows them to maintain accurate orientation and alignment during operation.

Customizing non-standard parts is one of the key benefits of using this product. With its high-precision capabilities, it allows manufacturers to produce customized parts that meet the specific needs of their clients. This includes parts that require precise dimensions, surface finishes, and other specialized features.

In conclusion, Stainless Steel CNC Lathes Machining Milling Customized Non-Standard Parts High-precision Machining Threaded Step Eccentric Shafts is a versatile toolset that offers numerous benefits for manufacturers who need to produce custom parts with high precision and efficiency. Its combination of advanced control systems, high-precision machining capabilities, and customizable components makes it an ideal choice for a wide range of applications.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Stainless steel CNC lathe machining milling customized non-standard parts high-precision machining Threaded Step Eccentric Shaft

1. What is CNC Machining?

CNC (Computer Numerical Control) machining is a process of using computer-controlled machines to produce parts by means of precise cutting and shaping operations.

2. Why Choose stainless steel for CNC Machining?

Stainless steel is a highly durable material that offers excellent corrosion resistance, making it ideal for use in demanding applications such as food processing, aerospace, and automotive manufacturing.

3. What types of non-standard parts can be CNC Machined with this technology?

Non-standard parts include those that require precision threading, eccentric shafts, or other unique shapes and sizes that cannot be easily produced using traditional machining methods.

4. Can I use a single CNC machine for the entire manufacturing process?

No, it’s recommended to use multiple CNC machines with different capabilities to handle different stages of the manufacturing process.

5. How do I select the right type of thread for my custom part?

The thread type should be chosen based on the requirements of the part, including its dimensions, weight, and intended application. The most commonly used thread types for custom parts include SAE J2283 and AWS G4.

6. Can you provide examples of high-precision machining with the Threaded Step Eccentric shaft?

Sure! One example is a custom engineered aircraft engine thrust arm that uses a Threaded Step Eccentric shaft for increased rigidity and durability. Another example is a precisionMedical equipment component that utilizes a Threaded Step Eccentric shaft for optimal control and stability during assembly.

7. How long does it take to manufacture a custom part using CNC Machining?

The time it takes to manufacture a custom part depends on various factors such as the complexity of the design, the materials being used, and the level of accuracy required. On average, it can take several weeks to months, depending on the specific needs of each project.

8. Are there any environmental or safety concerns associated with CNC Machining?

Yes, there are certain environmental and safety considerations when it comes to CNC Machining. It’s important to follow all relevant regulations and guidelines to minimize risks and ensure safe work conditions. This includes proper ventilation, adequate cleaning, and regular maintenance of machinery.

(Stainless steel CNC lathe machining milling customized non-standard parts high-precision machining Threaded Step Eccentric Shaft)

REQUEST A QUOTE

RELATED PRODUCTS

OEM China Manufacture Low Carbon Steel Shaft Helical Gear Shaft For Transmission Machine

Custom Metal Processing Service CNC Machine Spare Parts 5 Axis Precision Machining Parts Worm Gear Shaft

Professional Direct ing Practical Stainless Rod Steel Shaft Round Rod Bar Astm304 Sus304

Black Drive shaft Heavy Duty Machine Part MTZ Drive Shaft Cardan Drive shaft

Needle Roller Bearing 25v3724 90364-25012 Iko Bearing K 26x38x25 Auto Shaft Bearings Size 25x37x24.5