PRODUCT PARAMETERS

Description

Introduction to customizable 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel for Auto Tractor Motorcycle Ship Engine

customizable 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel for Auto Tractor Motorcycle Ship Engine are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of customizable 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel for Auto Tractor Motorcycle Ship Engine

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(customizable 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel for Auto Tractor Motorcycle Ship Engine)

Specification of customizable 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel for Auto Tractor Motorcycle Ship Engine

The customizable 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel is a high-performance abrasive tool designed specifically for precision grinding applications in the automotive, tractor, motorcycle, and ship engine industries. Engineered to meet the demanding requirements of crankshaft and camshaft grinding, this wheel delivers exceptional accuracy, durability, and efficiency, making it an ideal choice for manufacturers and repair workshops.

The grinding wheel is constructed using vitrified bonding technology, which ensures superior strength, thermal stability, and resistance to wear. This bonding method allows the wheel to maintain its shape and cutting performance even under high-speed operations and heavy loads. The customizable diameter range of 500-900mm ensures compatibility with a wide variety of grinding machines and applications, catering to different engine sizes and specifications.

The wheel is designed to handle the intricate geometries of crankshafts and camshafts, providing precise grinding with minimal vibration and heat generation. This results in a smoother finish and extends the lifespan of the grinding wheel. Its high-quality abrasive grains ensure consistent material removal rates, reducing downtime and improving productivity. Additionally, the vitrified bond allows for easy dressing, ensuring the wheel remains sharp and efficient throughout its lifecycle.

Customization options include variations in grit size, hardness, and structure, allowing users to tailor the wheel to specific grinding requirements. Whether it’s for rough grinding, finishing, or achieving ultra-fine surface finishes, this grinding wheel can be optimized for the task. Its versatility makes it suitable for a wide range of materials, including hardened steel, cast iron, and other alloys commonly used in engine components.

In summary, the 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel is a reliable, high-performance solution for precision grinding in the automotive and marine industries. Its customizable features, combined with exceptional durability and efficiency, make it an indispensable tool for achieving superior grinding results in engine manufacturing and maintenance.

(customizable 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel for Auto Tractor Motorcycle Ship Engine)

Applications of customizable 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel for Auto Tractor Motorcycle Ship Engine

The customizable 500-900mm vitrified bonded crankshaft and camshaft grinding wheel is a high-performance abrasive tool designed for precision grinding applications in the automotive, tractor, motorcycle, and ship engine industries. Engineered to meet the demanding requirements of modern engine manufacturing and maintenance, this grinding wheel is ideal for achieving superior surface finishes, dimensional accuracy, and extended tool life.

One of the key applications of this grinding wheel is in the machining of crankshafts and camshafts, which are critical components in internal combustion engines. The vitrified bond structure ensures exceptional hardness and thermal stability, allowing the wheel to withstand high grinding pressures and temperatures without losing its shape or efficiency. This makes it perfect for grinding hardened steel and alloy materials commonly used in engine components.

For automotive engines, the grinding wheel is used to refine crankshaft journals and camshaft lobes, ensuring smooth operation and optimal engine performance. In tractor engines, it helps maintain the durability and reliability of heavy-duty components, which are subjected to extreme loads and harsh operating conditions. Motorcycle engines benefit from the wheel’s precision grinding capabilities, enabling the production of lightweight yet robust parts that enhance performance and fuel efficiency.

In the ship engine industry, where components are exposed to corrosive environments and heavy wear, the grinding wheel’s vitrified bond provides excellent resistance to wear and chemical degradation. This ensures consistent performance and longevity, even in the most challenging applications.

The customizable nature of the 500-900mm grinding wheel allows it to be tailored to specific grinding requirements, such as grit size, bond composition, and wheel hardness. This flexibility ensures optimal results across a wide range of materials and applications, making it a versatile solution for engine manufacturers and repair workshops alike.

Overall, the vitrified bonded crankshaft and camshaft grinding wheel is an indispensable tool for achieving precision, efficiency, and durability in engine component manufacturing and maintenance. Its advanced design and customizable features make it a reliable choice for industries that demand the highest standards of quality and performance.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of customizable 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel for Auto Tractor Motorcycle Ship Engine

When it comes to precision grinding for crankshafts and camshafts in auto, tractor, motorcycle, and ship engines, the customizable 500-900mm vitrified bonded grinding wheel stands out as a reliable and efficient solution. Here are five frequently asked questions about this specialized grinding wheel:

1. **What makes the 500-900mm vitrified bonded grinding wheel suitable for crankshaft and camshaft grinding?**

This grinding wheel is designed with a vitrified bond, which ensures high strength, thermal stability, and excellent grinding performance. Its customizable size range of 500-900mm makes it versatile for various engine types, ensuring precise and consistent results for both crankshafts and camshafts.

2. **Can the grinding wheel be customized for specific applications?**

Yes, the grinding wheel can be tailored to meet specific requirements, such as grit size, hardness, and bond composition. This customization ensures optimal performance for different materials and grinding conditions, making it ideal for a wide range of engine components.

3. **How does the vitrified bond enhance the grinding process?**

The vitrified bond provides exceptional durability and heat resistance, reducing the risk of wheel wear and thermal damage during high-speed grinding. This results in a longer wheel life, reduced downtime, and consistent surface finish quality.

4. **Is this grinding wheel suitable for high-precision applications?**

Absolutely. The 500-900mm vitrified bonded grinding wheel is engineered for high-precision grinding, ensuring tight tolerances and smooth finishes. It is particularly effective for applications requiring fine surface finishes and dimensional accuracy, such as in automotive and marine engines.

5. **What maintenance is required for this grinding wheel?**

Regular dressing and truing are essential to maintain the wheel’s performance and shape. Proper storage and handling are also important to prevent damage. With proper care, this grinding wheel delivers long-lasting performance and reliability.

In summary, the customizable 500-900mm vitrified bonded grinding wheel is a top choice for crankshaft and camshaft grinding in various engines. Its adaptability, precision, and durability make it an indispensable tool for achieving superior grinding results.

(customizable 500-900mm Vitrified Bonded Crankshaft and Cam Shaft Grinding Wheel for Auto Tractor Motorcycle Ship Engine)

REQUEST A QUOTE

RELATED PRODUCTS

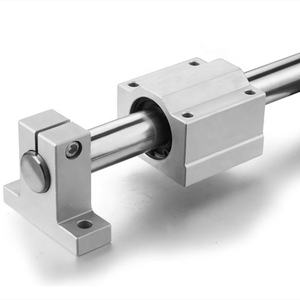

Low Friction Brass and Stainless Steel Self-Reversing Screw Nut CNC Machined Reciprocating Screw Self Reversing Screw Shaft

Worm Gear Electric Motor Long Rotor Stainless Steel Shaft

High Quality Propeller shaft Drive shaft OEM 1-37171058-0 for ISUZU Trucks drive shafts

Bus Spare Parts OEM Axle Drive Shaft Custom Transmission Driver Shafts for Higer Kinglong Zhongtong Bus

WangLi CNC Machinery Custom Pinion shaft Drive Main shaft OEM Forging Steel Transmission Large Spline Shaft