PRODUCT PARAMETERS

Description

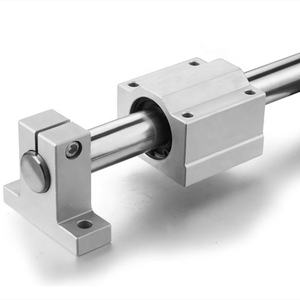

Introduction to ceramic rod wash motor rotor ceramic shaft

ceramic rod wash motor rotor ceramic shaft are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of ceramic rod wash motor rotor ceramic shaft

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(ceramic rod wash motor rotor ceramic shaft)

Specification of ceramic rod wash motor rotor ceramic shaft

The ceramic rod wash motor rotor ceramic shaft is a high-performance component designed for durability, efficiency, and precision in demanding applications. Crafted from advanced ceramic materials, this shaft offers exceptional mechanical strength, thermal stability, and resistance to wear and corrosion. Its unique properties make it an ideal choice for use in wash motors, where exposure to water, detergents, and high-speed operations can compromise the integrity of traditional metal shafts.

The ceramic shaft is engineered to withstand extreme temperatures, ensuring consistent performance even in high-heat environments. Its low thermal expansion coefficient minimizes the risk of deformation, maintaining dimensional stability under varying operating conditions. Additionally, the ceramic material’s inherent hardness provides superior resistance to abrasion, extending the lifespan of the shaft and reducing maintenance requirements.

One of the standout features of this ceramic shaft is its lightweight design. Compared to metal alternatives, the ceramic shaft significantly reduces the overall weight of the rotor, contributing to improved energy efficiency and reduced operational strain on the motor. This lightweight characteristic also enhances the motor’s responsiveness and speed, making it suitable for high-speed applications.

The ceramic rod wash motor rotor ceramic shaft is also highly resistant to chemical corrosion, making it an excellent choice for environments where exposure to harsh chemicals or detergents is common. Its non-porous surface prevents the buildup of contaminants, ensuring smooth operation and minimizing the risk of mechanical failure.

Precision-engineered to meet stringent quality standards, this ceramic shaft ensures optimal alignment and balance within the motor assembly. Its smooth surface finish reduces friction, further enhancing efficiency and reducing energy consumption. Whether used in household appliances, industrial machinery, or specialized equipment, the ceramic rod wash motor rotor ceramic shaft delivers unmatched performance, reliability, and longevity, making it a superior choice for modern motor applications.

(ceramic rod wash motor rotor ceramic shaft)

Applications of ceramic rod wash motor rotor ceramic shaft

Ceramic rod wash motor rotor ceramic shafts are revolutionizing the efficiency and durability of modern washing machines. These advanced components are crafted from high-performance ceramics, such as zirconia or alumina, which offer exceptional mechanical and thermal properties. Their application in wash motor rotors ensures superior performance, longevity, and energy efficiency, making them an ideal choice for both residential and commercial washing appliances.

One of the primary advantages of ceramic shafts is their remarkable resistance to wear and corrosion. Unlike traditional metal shafts, ceramic materials are immune to rust and degradation caused by water, detergents, and other chemicals commonly used in washing machines. This ensures a longer lifespan for the motor, reducing maintenance costs and downtime. Additionally, ceramic shafts exhibit excellent dimensional stability, maintaining their shape and precision even under high-speed rotation and extreme temperature fluctuations.

Another key benefit is the lightweight nature of ceramic materials. The reduced weight of the rotor shaft minimizes the overall load on the motor, leading to lower energy consumption and improved operational efficiency. This not only contributes to energy savings but also enhances the environmental sustainability of the appliance. Furthermore, the low friction coefficient of ceramics reduces heat generation and mechanical losses, ensuring smoother and quieter operation.

Ceramic shafts also excel in high-stress environments, offering exceptional strength and rigidity. This makes them highly resistant to bending, cracking, or deformation, even under heavy loads or prolonged use. As a result, they provide reliable performance in demanding washing cycles, such as those involving large loads or high-speed spinning.

In summary, the application of ceramic rod wash motor rotor ceramic shafts in washing machines delivers a combination of durability, efficiency, and performance. Their unique properties make them a superior alternative to traditional materials, ensuring longer-lasting appliances, reduced energy consumption, and enhanced user satisfaction. As the demand for more efficient and sustainable home appliances grows, ceramic shafts are poised to play a pivotal role in the future of washing machine technology.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of ceramic rod wash motor rotor ceramic shaft

Ceramic rod wash motor rotors with ceramic shafts are increasingly popular in various industries due to their durability, efficiency, and resistance to harsh conditions. Here are five frequently asked questions about these components:

1. **What are the benefits of using a ceramic shaft in a wash motor rotor?**

Ceramic shafts offer exceptional hardness, wear resistance, and thermal stability, making them ideal for high-performance applications. They are also corrosion-resistant, which is crucial in wash motors exposed to water, detergents, and chemicals. Additionally, ceramic shafts reduce friction, leading to improved energy efficiency and longer motor life.

2. **How does a ceramic shaft compare to a traditional metal shaft?**

Unlike metal shafts, ceramic shafts are lightweight, non-conductive, and non-magnetic, which minimizes energy loss and heat generation. They are also more resistant to deformation under high stress and extreme temperatures. This makes ceramic shafts a superior choice for demanding environments where metal shafts might fail or degrade over time.

3. **Are ceramic shafts suitable for high-speed applications?**

Yes, ceramic shafts are ideal for high-speed applications due to their low density and high strength. They can withstand rapid rotations without warping or losing structural integrity, ensuring consistent performance and reliability in high-speed wash motors.

4. **Can ceramic shafts handle exposure to harsh chemicals and water?**

Absolutely. Ceramic materials, such as alumina or zirconia, are inherently resistant to corrosion and chemical damage. This makes them perfect for wash motor rotors that operate in environments with frequent exposure to water, detergents, and cleaning agents.

5. **What maintenance is required for ceramic rod wash motor rotors?**

One of the key advantages of ceramic shafts is their low maintenance requirements. Their resistance to wear, corrosion, and thermal stress means they rarely need replacement or repair. Regular inspections to ensure proper alignment and lubrication of other motor components are usually sufficient to maintain optimal performance.

In summary, ceramic rod wash motor rotors with ceramic shafts provide a durable, efficient, and low-maintenance solution for demanding applications. Their unique properties make them a reliable choice for industries requiring high-performance motor components.

(ceramic rod wash motor rotor ceramic shaft)

REQUEST A QUOTE

RELATED PRODUCTS

Universal Joint U-joint Cross Bearing 5-134X universal steering shaft joint

SMD 5 pin metal handle diameter 6mm Flat shaft shaft 18/20/30 brake EC11 rotary encoder

Helical Gear s NMRV25/30//40/63/75/90/110 Worm Gear Speed Reducer 14mm Input Shaft Diameter For

Long Shaft Steel Forged Subsea Oil Throttle Valve Mud Pump Joint Oilfield Stabilizer Metal Shaft

Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing