PRODUCT PARAMETERS

Description

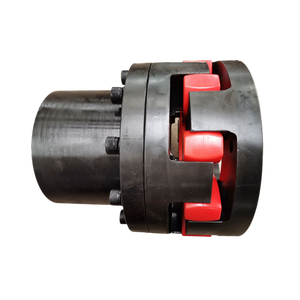

Introduction to Aluminum Connecting Shaft Sleeve CNC Machining Services Factory Turning Milling Chengshuo Hardware Machined

Aluminum Connecting Shaft Sleeve CNC Machining Services Factory Turning Milling Chengshuo Hardware Machined are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Aluminum Connecting Shaft Sleeve CNC Machining Services Factory Turning Milling Chengshuo Hardware Machined

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Aluminum Connecting Shaft Sleeve CNC Machining Services Factory Turning Milling Chengshuo Hardware Machined)

Specification of Aluminum Connecting Shaft Sleeve CNC Machining Services Factory Turning Milling Chengshuo Hardware Machined

Aluminum connecting shaft sleeves are commonly used in mechanical equipment, such as air compressors and pumps, to ensure reliable and secure connections between the shaft and the sleeve. At our factory, we offer high-quality CNC machining services for aluminum connecting shaft sleeves, ensuring accurate and precise cutting.

Our CNC turning mill is equipped with the latest technology and machinery, allowing us to produce parts with consistent quality and accuracy. We have a team of experienced machinists who are skilled at operating this machine, ensuring that each part is produced to the highest standard.

We also use state-of-the-art software tools to analyze and control the cutting process, which helps us to optimize our production processes and reduce waste. Our facility has all the necessary safety measures in place to protect our workers from potential hazards during the manufacturing process.

In addition to providing our customers with high-quality aluminum connecting shaft sleeves, we also offer comprehensive after-sales support services. This includes maintenance and repair services, as well as technical assistance to help our customers troubleshoot any issues they may encounter.

At our factory, we take pride in providing our customers with exceptional service and ensuring their satisfaction with every product we produce. Contact us today to learn more about our aluminum connecting shaft sleeve CNC machining services and how we can help you achieve your engineering goals.

(Aluminum Connecting Shaft Sleeve CNC Machining Services Factory Turning Milling Chengshuo Hardware Machined)

Applications of Aluminum Connecting Shaft Sleeve CNC Machining Services Factory Turning Milling Chengshuo Hardware Machined

Aluminum connecting shaft sleeves are used in various applications such as industrial machinery, automotive industry, and even consumer products. One of the primary benefits of aluminum connecting shaft sleeves is their lightweight and durable nature. They are made from high-strength aluminum and can withstand harsh conditions, making them ideal for use in demanding environments.

Another advantage of aluminum connecting shaft sleeves is their corrosion resistance. Because they are made from high-quality materials, they are resistant to corrosion, which means that they will not rust or corrode over time, saving maintenance costs and the life of the equipment.

CNC machining services can be provided for the manufacture of aluminum connecting shaft sleeves. This involves using advanced computer-aided design (CAD) software to create precise designs for the sleeve, followed by using a computer-controlled milling machine to the sleeve from raw metal. The final result is a part that is precisely crafted and meets all necessary specifications.

One of the main advantages of CNC machining services is that they can produce a wide range of sizes and shapes, making it easy to find the right part for specific applications. Additionally, the use of high-quality materials and advanced technology ensures that the resulting parts are of the highest quality.

Aluminum connecting shaft sleeves are an essential component in many industries, and there is no limit to the number of applications they can be used in. From precision engineering to aerospace, aluminum connecting shaft sleeves are versatile and can be customized to meet the unique needs of each project.

At Chengshuo Hardware Machined, we offer a wide range of CNC machining services to help you get the best results from your aluminum connecting shaft sleeves. Whether you need a small batch of parts or a large quantity, our experienced team will work with you to ensure that the job is done to the highest standards possible.

In conclusion, aluminum connecting shaft sleeves are a versatile and highly functional component that can be used in a variety of applications. CNC machining services make it possible to create precise and high-quality parts quickly and efficiently, ensuring that your project is completed on time and to your satisfaction. Contact us today to learn more about how we can help you get the best results from your aluminum connecting shaft sleeves.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Aluminum Connecting Shaft Sleeve CNC Machining Services Factory Turning Milling Chengshuo Hardware Machined

1. What is aluminum connecting shaft sleeve CNC machining services?

Aluminum connecting shaft sleeves (CSs) are used in various applications, such as food processing equipment, packaging machinery, and beverage machinery. They are designed to connect the shaft of a machine with the rotating parts without the need for a complete seal.

CNC machining services provide a high-quality solution for manufacturing aluminum CSs. Our skilled technicians use advanced CNC machines to produce precise and accurate parts, ensuring that they meet the highest standards of quality and durability.

2. What materials can we work with?

We can work with various types of aluminum, including rolled, extruded, or cast aluminum. We also have experience working with other materials, such as titanium and stainless steel, depending on the specific requirements of your application.

3. How long does it take to manufacture an aluminum CS?

The time required to manufacture an aluminum CS depends on several factors, including the complexity of the part, the material being used, and the production rate. However, our team has extensive experience in optimizing the manufacturing process to ensure fast and efficient delivery.

4. Can you handle customized designs?

Yes, we can handle customized designs for aluminum CSs. Our experienced designers will work closely with you to understand your needs and develop a unique solution that meets your specific requirements.

5. What are the advantages of using aluminum CSs?

One of the main advantages of using aluminum CSs is their lightweight properties. This makes them ideal for use in applications where weight reduction is crucial, such as food processing equipment and beverage machinery. Additionally, aluminum CSs are durable and can withstand wear and tear, which makes them an excellent choice for harsh operating environments.

In conclusion, aluminum CSs from our factory turning milling Chengshuo Hardware Machined offer numerous benefits, including improved efficiency, longer life spans, and reduced maintenance costs. If you require aluminum CSs for your project, please don’t hesitate to contact us for more information.

(Aluminum Connecting Shaft Sleeve CNC Machining Services Factory Turning Milling Chengshuo Hardware Machined)

REQUEST A QUOTE

RELATED PRODUCTS

Low Friction Brass and Stainless Steel Self-Reversing Screw Nut CNC Machined Reciprocating Screw Self Reversing Screw Shaft

Factory Customizable OEM Drawing Products Elastic Coupling Cardan Drive Shaft Plum-Shaped Steel OEM Drawing Available

Custom Cnc Hrc61~65 8Mm Motor Shaft S304 S316 Stainless Steel Motor Armature Shaft

Customized crankshaft for engine Forging Steel OEM crankshaft professional manufacture, crankshaft

Black Drive shaft Heavy Duty Machine Part MTZ Drive Shaft Cardan Drive shaft