PRODUCT PARAMETERS

Description

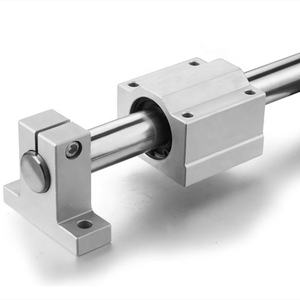

Introduction to Custom Cnc Machined Service OEM High Precision Cnc Machining Turning Stainless Steel Aluminum Alloy Metal Pin Shaft Parts

Custom Cnc Machined Service OEM High Precision Cnc Machining Turning Stainless Steel Aluminum Alloy Metal Pin Shaft Parts are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Custom Cnc Machined Service OEM High Precision Cnc Machining Turning Stainless Steel Aluminum Alloy Metal Pin Shaft Parts

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Custom Cnc Machined Service OEM High Precision Cnc Machining Turning Stainless Steel Aluminum Alloy Metal Pin Shaft Parts)

Specification of Custom Cnc Machined Service OEM High Precision Cnc Machining Turning Stainless Steel Aluminum Alloy Metal Pin Shaft Parts

Our custom CNC machining service is committed to providing high-quality parts for your specific needs. We take pride in producing parts that meet or exceed industry standards and are manufactured using the latest technology and equipment.

When it comes to specifications, we understand the importance of accuracy and precision when it comes to your part requirements. Our experienced engineers work closely with you to ensure that your part meets all necessary tolerances, including roundness, flatness, and thread matched. We also use advanced software to create precise specifications and monitor every step of the manufacturing process to ensure consistency and quality control.

In addition to the technical specifications, we also pay close attention to the material properties of the part being machined. Stainless steel, aluminum alloy, and metal pin shafts are just a few examples of the materials we work with. Each material has its own unique properties and characteristics that must be taken into account when selecting the right tooling and equipment for the job.

Our team of skilled technicians uses only the highest-quality tools and equipment to produce our parts, ensuring that they meet or exceed even the most requirements. We also have access to a wide range of additional components and accessories, allowing us to customize the final product to meet your exact specifications.

At our company, we believe that excellent customer service is essential to building long-term relationships with clients. That’s why we’re always available to answer questions, provide guidance, and help ensure that your project is completed on time and within budget.

Whether you need a small batch of parts for a single project or large quantities for production runs, we can handle it all. Contact us today to learn more about our custom CNC machining service and how we can help bring your ideas to life.

(Custom Cnc Machined Service OEM High Precision Cnc Machining Turning Stainless Steel Aluminum Alloy Metal Pin Shaft Parts)

Applications of Custom Cnc Machined Service OEM High Precision Cnc Machining Turning Stainless Steel Aluminum Alloy Metal Pin Shaft Parts

Custom CNC Machined Service offers high precision cnc machining turning services for stainless steel, aluminum alloy, metal pin shaft parts. Our experienced technicians can produce components with minimal tolerances and consistent quality.

We use state-of-the-art equipment to ensure that every part is produced to the highest standards. Our machines are designed to handle a wide range of materials, including stainless steel, aluminum, and metal pin shafts. We also offer customization options to meet the unique needs of our clients.

In addition to cnc machining, we also provide heat treatment services to improve the performance and durability of your components. This includes heating and cooling, as well as the addition of coatings or other treatments.

Our commitment to customer satisfaction is reflected in our attention to detail and prompt response times. Whether you need a small part or a large project, we have the expertise and resources to get the job done right the first time.

Contact us today to learn more about our custom cnc machined service and how we can help bring your project to life. With our experience and high-quality products, you can be confident that your cnc machined parts will meet your exact specifications and perform flawlessly.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Custom Cnc Machined Service OEM High Precision Cnc Machining Turning Stainless Steel Aluminum Alloy Metal Pin Shaft Parts

1. What is CNC Machining and how does it differ from traditional machining methods?

CNC (Computer Numerical Control) Machining is a process that uses computer software to control the movement of a machine’s cutting tools to produce parts. It allows for greater precision and accuracy than traditional manual machining methods, making it ideal for creating complex and high-quality parts.

2. What are some benefits of using custom CNC machined service for production of stainless steel aluminum alloy metal pin shaft parts?

Using custom CNC machined service can provide several benefits, including increased productivity, improved quality control, reduced downtime, and faster lead times. By working with a reputable supplier who specializes in CNC machining, you can ensure that your parts meet all necessary standards and specifications.

3. How long does it take to produce customized CNC machined parts compared to traditional machining methods?

The time it takes to produce customized CNC machined parts will depend on various factors, such as the complexity of the part, the size and type of tool required, and the manufacturer’s production schedule. However, in general, it can take anywhere from a few days to several weeks for custom CNC parts to be produced.

4. What kind of materials can I use when working with custom CNC machined services?

Custom CNC machined services can work with a wide range of materials, including stainless steel, aluminum, and other alloys. The choice of material will depend on the specific requirements of your project and the expertise of your supplier.

5. Can I receive sample parts before committing to a large order?

Yes, many custom CNC machining companies offer sample parts to their customers to ensure that they meet their requirements before committing to a large order. This allows you to make an informed decision about whether the custom CNC machining services are right for your needs.

(Custom Cnc Machined Service OEM High Precision Cnc Machining Turning Stainless Steel Aluminum Alloy Metal Pin Shaft Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Customizable OEM Drawing Products Elastic Coupling Cardan Drive Shaft Plum-Shaped Steel OEM Drawing Available

High Precision Linear Hollow shaft 3mm 55mm 60mm 70mm 80mm To 150mm Stainless Steel Chromed Hardened Linear Bearing Steel Shaft

Worm Gear Electric Motor Long Rotor Stainless Steel Shaft

China made professional customized different shape spur gear and shaft

Customized crankshaft for engine Forging Steel OEM crankshaft professional manufacture, crankshaft