PRODUCT PARAMETERS

Description

Introduction to Customized crankshaft for engine Forging Steel crankshaft professional manufacture crankshaft

Customized crankshaft for engine Forging Steel crankshaft professional manufacture crankshaft are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Customized crankshaft for engine Forging Steel crankshaft professional manufacture crankshaft

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Customized crankshaft for engine Forging Steel crankshaft professional manufacture crankshaft)

Specification of Customized crankshaft for engine Forging Steel crankshaft professional manufacture crankshaft

A customized crankshaft is an essential component of an engine that allows the engine to run smoothly and efficiently. It consists of a set of rotating parts that transfer power from the fuel to the wheels. The crankshaft is designed to match the specifications of the engine, ensuring that it functions correctly and produces the desired output.

In order to produce customized crankshafts, the manufacturer will need to understand the specific requirements of the engine. This may include details such as the size of the crankcase, the type of iron used in the casting, and the design of the engine’s. Once these specifications have been identified, the manufacturer will use high-quality materials to shape and polish the crankshaft to meet the exact requirements.

Customized crankshafts can also be produced with unique features such as journals or bosses that allow for specific tolerances in the material being forged. This can result in a stronger and more durable crankshaft that lasts longer than standard components.

One advantage of producing customized crankshafts is that they can be tailored to meet the specific needs of each individual application. For example, a customized crankshaft may be designed specifically for use in a high-performance vehicle, while another may be optimized for use in a smaller car or truck.

In conclusion, customizing crankshafts is a critical process for ensuring that engines operate at their maximum potential. By understanding the specific requirements of each engine and using high-quality materials to shape and polish the crankshaft, manufacturers can produce customized crankshafts that provide superior performance and durability.

(Customized crankshaft for engine Forging Steel crankshaft professional manufacture crankshaft)

Applications of Customized crankshaft for engine Forging Steel crankshaft professional manufacture crankshaft

A customized crankshaft is an important component in engine forging steel crankshafts, which play a crucial role in the performance and efficiency of engines. The custom crankshaft design allows manufacturers to tailor the size, shape, and configuration of the shaft to meet specific requirements for different applications.

One key advantage of using a customized crankshaft is that it can improve the strength and durability of the engine. By optimizing the design of the shaft, manufacturers can create a more robust and resistant component that can withstand the wear and tear of daily use. This can result in improved engine performance, increased fuel efficiency, and reduced maintenance costs.

Another benefit of using a customized crankshaft is that it can improve the reliability of the engine. By carefully designing the shaft to optimize its、, manufacturers can reduce the risk of failure or damage during operation. This can lead to longer lifespan for the engine and lower replacement costs over time.

Additionally, custom crankshafts can improve the emissions of the engine. Engine forge steel is often used to produce high-quality forged crankshafts due to its strong and durable properties. However, some types of forged crankshafts may not be suitable for certain engine configurations or operating conditions. A customized crankshaft ensures that the engine is designed with the right specifications and components, resulting in cleaner emissions and better overall performance.

In conclusion, customized crankshafts are an essential component for engine forging steel crankshafts. By optimizing the design of the shaft, manufacturers can create a more robust, reliable, and efficient engine that meets specific application requirements. Whether you’re a seasoned engineer or just starting out, using a customized crankshaft can help you achieve your goals and take your engine performance to the next level.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Customized crankshaft for engine Forging Steel crankshaft professional manufacture crankshaft

1. What is a customized crankshaft and how does it differ from a standard crankshaft?

A customized crankshaft is a crankshaft that has been specifically designed to meet the specific requirements of an engine. This may include modifications such as increased strength, improved fuel efficiency, or increased durability.

2. How can I know if my crankshaft needs custom manufacturing?

If your crankshaft is showing signs of wear or damage, or if you want to make improvements to its performance, then it may be time for customization. Professional engine forging steel manufacturers will be able to assess your crankshaft’s condition and provide recommendations on whether customization is necessary.

3. Can customization affect the quality of the final product?

Yes, customization can affect the quality of the final product. By modifying the design of the crankshaft, manufacturers can improve its strength, stability, and performance. However, it is important to work with reputable and experienced manufacturers who have the expertise and equipment needed to perform customization to ensure that the final product meets your specifications.

4. Who performs customized crankshafts?

Customized crankshafts are typically manufactured by professional engine forging steel manufacturers. These companies have experience in designing and manufacturing custom crankshafts that meet the unique needs of their customers. They use high-quality materials and state-of-the-art equipment to create customized crankshafts that are strong, durable, and reliable.

5. Are customized crankshafts more expensive than standard ones?

Customized crankshafts may be more expensive than standard ones, but they often offer significant performance benefits. By improving the strength, stability, and fuel efficiency of the engine, customized crankshafts can help increase overall engine performance. Additionally, the investment in custom crankshafts may pay off in reduced maintenance costs over the life of the engine.

(Customized crankshaft for engine Forging Steel crankshaft professional manufacture crankshaft)

REQUEST A QUOTE

RELATED PRODUCTS

Customized assembled Golf Iron Steel Graphite Golf Shaft with Grips

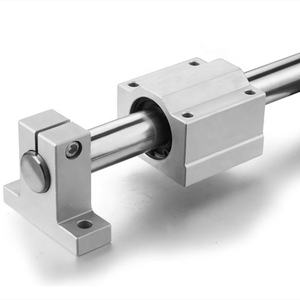

High Precision carbon steel bar 3 to 120mm diameter hard chrome plated linear shaft

16mm Linear shaft sbr16uu Linear sliding bearing block

Spare Parts Komatsu 6D170-2 Rocker Arm Shaft 6162-43-5300

For TRANSIT Original drive shaft mounting bracket Centre bearing part CC114826AA 1810012 6649122