PRODUCT PARAMETERS

Description

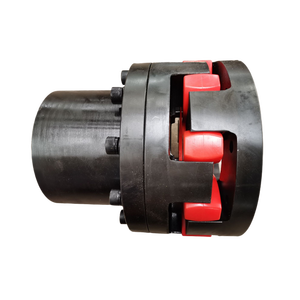

Introduction to Customized Professional Forging Steel Crankshaft Professional Machining Services for Engine Crankshaft

Customized Professional Forging Steel Crankshaft Professional Machining Services for Engine Crankshaft are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Customized Professional Forging Steel Crankshaft Professional Machining Services for Engine Crankshaft

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Customized Professional Forging Steel Crankshaft Professional Machining Services for Engine Crankshaft)

Specification of Customized Professional Forging Steel Crankshaft Professional Machining Services for Engine Crankshaft

Customized Professional Forging Steel Crankshaft and Professional Machining Services are designed to meet the highest standards of precision, durability, and performance for engine crankshafts. Our services cater to a wide range of industries, including automotive, marine, aerospace, and heavy machinery, ensuring that every crankshaft is tailored to the specific requirements of the engine it powers.

Our forging process utilizes high-quality alloy steel, which is carefully selected for its superior strength, wear resistance, and ability to withstand extreme conditions. The steel is heated to optimal temperatures and forged under controlled conditions to achieve a dense, uniform grain structure, enhancing the crankshaft’s mechanical properties and longevity. This ensures that the crankshaft can handle high torque, stress, and rotational forces without compromising performance.

The machining process is carried out with state-of-the-art CNC (Computer Numerical Control) equipment, guaranteeing precision and consistency in every component. Our advanced machining techniques allow us to achieve tight tolerances and exact specifications, ensuring a perfect fit and seamless operation within the engine. Key features such as journal diameters, counterweights, and oil passages are meticulously crafted to meet OEM (Original Equipment Manufacturer) standards or custom design requirements.

We offer a wide range of customization options, including material selection, heat treatment, surface finishing, and balancing. Heat treatment processes such as quenching and tempering are applied to enhance hardness and fatigue resistance, while surface treatments like nitriding or shot peening improve wear resistance and reduce friction. Dynamic balancing is performed to minimize vibrations and ensure smooth engine operation.

Our team of experienced engineers and technicians works closely with clients to understand their unique needs and deliver solutions that exceed expectations. Whether you require a single prototype or large-scale production, we are committed to providing high-quality, reliable crankshafts that deliver exceptional performance and durability. Trust us to be your partner in achieving optimal engine efficiency and reliability with our professional forging and machining services.

(Customized Professional Forging Steel Crankshaft Professional Machining Services for Engine Crankshaft)

Applications of Customized Professional Forging Steel Crankshaft Professional Machining Services for Engine Crankshaft

Customized professional forging steel crankshaft machining services are essential for the production of high-performance engine crankshafts, which are critical components in various industries, including automotive, marine, aerospace, and heavy machinery. These services cater to the specific needs of manufacturers and engineers who require precision-engineered crankshafts that meet exacting standards for durability, strength, and performance.

The process begins with the selection of high-quality steel, which is forged under controlled conditions to create a robust and durable crankshaft blank. Customization is a key aspect of these services, allowing for the creation of crankshafts tailored to unique engine designs, performance requirements, and operational conditions. Whether it’s for high-speed racing engines, heavy-duty industrial machinery, or marine propulsion systems, the ability to customize ensures optimal performance and longevity.

Professional machining services further enhance the forged crankshaft by employing advanced CNC (Computer Numerical Control) technology. This ensures precise dimensions, tight tolerances, and superior surface finishes, which are critical for minimizing friction, reducing wear, and improving overall engine efficiency. The machining process includes operations such as turning, milling, grinding, and balancing, all of which are performed with meticulous attention to detail.

Applications of these customized crankshafts are vast. In the automotive industry, they are used in high-performance vehicles, trucks, and motorcycles, where reliability and power output are paramount. In marine engines, they withstand harsh operating conditions, including saltwater exposure and high loads. Aerospace applications demand lightweight yet strong crankshafts to ensure safety and efficiency in aircraft engines. Additionally, industrial machinery relies on these components for heavy-duty operations, where consistent performance under extreme stress is required.

By leveraging customized professional forging and machining services, manufacturers can achieve crankshafts that deliver superior performance, extended service life, and reduced maintenance costs. These services not only meet but often exceed industry standards, making them indispensable for industries that depend on precision-engineered components for their critical applications.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Customized Professional Forging Steel Crankshaft Professional Machining Services for Engine Crankshaft

Customized professional forging steel crankshaft machining services are essential for ensuring the durability, precision, and performance of engine crankshafts. Here are five frequently asked questions (FAQs) about these services to help you understand their importance and benefits:

1. **What materials are used in forging steel crankshafts?**

High-quality alloy steels, such as 42CrMo4, 4340, and other specialized grades, are commonly used in forging crankshafts. These materials are chosen for their exceptional strength, wear resistance, and ability to withstand high stress and temperatures, making them ideal for demanding engine applications.

2. **Why is customization important for crankshaft machining?**

Customization ensures that the crankshaft is tailored to meet the specific requirements of the engine, such as size, weight, and performance needs. This level of precision enhances engine efficiency, reduces vibration, and extends the lifespan of the crankshaft, making it a critical aspect of high-performance engines.

3. **What machining processes are involved in crankshaft production?**

The machining process includes turning, milling, grinding, and heat treatment. Advanced CNC machines are used to achieve precise dimensions and surface finishes, while heat treatment processes like quenching and tempering enhance the material’s hardness and durability.

4. **How do these services ensure quality and reliability?**

Reputable service providers adhere to strict quality control standards, such as ISO certifications, and conduct rigorous testing, including ultrasonic testing, magnetic particle inspection, and dimensional checks. These measures ensure that the crankshafts meet or exceed industry standards for performance and safety.

5. **What industries benefit from customized crankshaft machining services?**

Industries such as automotive, marine, aerospace, and heavy machinery rely on these services for high-performance engines. Whether for passenger vehicles, commercial trucks, ships, or industrial equipment, customized crankshafts play a vital role in optimizing engine performance and reliability.

By choosing professional forging and machining services, you can ensure that your crankshafts are built to the highest standards, delivering unmatched performance and longevity for your engines.

(Customized Professional Forging Steel Crankshaft Professional Machining Services for Engine Crankshaft)

REQUEST A QUOTE

RELATED PRODUCTS

Quality Guarantee Aluminum shaft customization Aluminum shaft processing small shaft processing

Mining Carbon Steel Forging Double Helical Large Gear Shaft

Customized Manufacturing Types Precision Alloy Aluminum Stainless Steel Long Linear Shafts

Large OEM Machining Forged 42CrMo High quality Grinding Long Metal forged steel spline shaft

Bulldozer Part Komatsu D65px-16 Shaft 14X-15-52120 14X1552120