PRODUCT PARAMETERS

Description

Introduction to Factory quality rotor stator pump parts plaster machine screw pump rotor fixed shaft

Factory quality rotor stator pump parts plaster machine screw pump rotor fixed shaft are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Factory quality rotor stator pump parts plaster machine screw pump rotor fixed shaft

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Factory quality rotor stator pump parts plaster machine screw pump rotor fixed shaft)

Specification of Factory quality rotor stator pump parts plaster machine screw pump rotor fixed shaft

The Factory Top Quality Rotor Stator Pump Parts Plaster Equipment Screw Pump Blades Fixed Shaft is crafted for high-performance applications in industrial plastering, slurry transfer, and thick material handling. Developed to withstand demanding functional problems, these elements guarantee longevity, accuracy, and dependability.

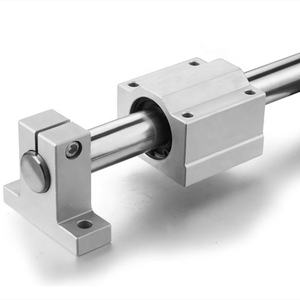

** Blades Specifications **: The blades is precision-machined from set stainless-steel or corrosion-resistant alloys, ensuring resistance to abrasion, chemical wear, and high-pressure atmospheres. Its helical account is maximized for smooth product circulation, reducing disturbance and taking full advantage of performance. The blades’s dimensions are tailored to fit standard screw pump settings up, with tolerances maintained within ± 0.01 mm for smooth assimilation. Surface treatments, such as nitriding or ceramic coating, boost solidity and expand service life.

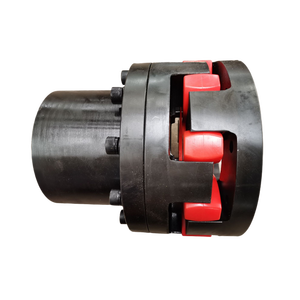

** Stator Specifications **: The stator is crafted from wear-resistant elastomers like nitrile rubber (NBR) or polyurethane (PU), picked for compatibility with rough plaster combinations and differing pH levels. Its inner helical dental caries matches the blades’s geometry, developing a limited seal for regular stress buildup. The stator’s robust style resists contortion under high torque, ensuring very little energy loss. Temperature level resistance varies from -20 ° C to +120 ° C, ideal for hot or cool plaster applications.

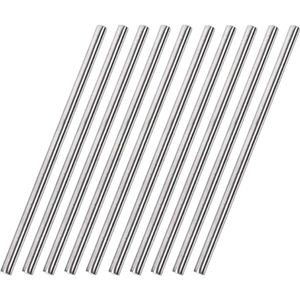

** Fixed Shaft Specifications **: The taken care of shaft is constructed from high-tensile carbon steel or alloy, heat-treated for superior stamina and fatigue resistance. It features precision-ground surface areas and anti-corrosion finishes to avoid wear in wet or chemically aggressive atmospheres. The shaft’s rigid layout ensures secure blades placement, lowering vibration and mechanical tension. Keyway or spline setups are readily available for secure combining with drive systems.

** General Specs **: The setting up runs at stress up to 15 bar and circulation prices flexible to 50 m ³/ h, depending upon pump size. Components adhere to ISO 9001 criteria for quality assurance. Personalization choices consist of varied rotor-stator voids, worldly grades, and dimensional modifications to suit details plaster formulas or maker needs.

Perfect for building and construction, mining, and making markets, these rotor-stator pump components deliver unparalleled efficiency in managing thick, unpleasant plaster combinations while ensuring minimal downtime and maintenance. Engineered for longevity and efficiency, they are an important upgrade for commercial screw pumps calling for accuracy and integrity.

(Factory quality rotor stator pump parts plaster machine screw pump rotor fixed shaft)

Applications of Factory quality rotor stator pump parts plaster machine screw pump rotor fixed shaft

Factory-quality blades stator pump components, consisting of precision-engineered blades, stators, and repaired shafts, are vital components in industrial pumping systems designed for demanding applications. These components are important to the effective operation of plaster machines and screw pumps, where reliability, toughness, and efficiency under harsh problems are non-negotiable.

In plaster machines, rotor-stator settings up play a main role in mixing, transferring, and splashing plaster or mortar. The blades’s helical style, coupled with the stator’s elastomeric lining, creates a progressive dental caries that moves thick plaster blends efficiently without clogging. The repaired shaft ensures exact placement of the rotor, minimizing resonance and use even when taking care of unpleasant products. This setup is important for building applications, such as wall plastering, floor screeding, and attractive surfaces, where consistent flow and pressure are important for uniform application.

Screw pumps furnished with durable rotor-stator parts and repaired shafts are widely made use of in markets calling for the transfer of high-viscosity or shear-sensitive fluids. In oil and gas, these pumps handle piercing muds, petroleum, and thick hydrocarbons. The fixed shaft’s rigid structure maintains rotor-stator alignment under extreme stress, avoiding leaks and prolonging life span. Similarly, in wastewater treatment, screw pumps with factory-quality parts efficiently move sludge and slurry, resisting rust from chemicals and rough particles.

The taken care of shaft’s function can not be overemphasized– it makes sure mechanical security, decreases power loss from misalignment, and supports hefty lots in constant operations. Combined with rotors and stators made from hardened alloys, stainless-steel, or wear-resistant polymers, these components endure thermal growth, chemical direct exposure, and mechanical anxiety.

Factory-quality parts are engineered to exact tolerances, minimizing downtime and upkeep expenses. Whether in building and construction, chemical handling, food production, or mining, the synergy in between rotor-stator settings up and fixed shafts assurances consistent performance, functional safety, and lasting cost performance. Investing in top-quality components guarantees your tools satisfies market standards, providing reliability in the most difficult environments.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory quality rotor stator pump parts plaster machine screw pump rotor fixed shaft

**What materials are used in Factory Quality Rotor Stator Pump Parts for plaster machines?**

The rotor, stator, and fixed shaft are typically made from high-grade materials like hardened stainless steel, abrasion-resistant polymers, or nitrile rubber. These materials ensure durability, corrosion resistance, and the ability to handle abrasive plaster mixtures without premature wear.

**How long do these screw pump rotor and stator components last under heavy use?**

With proper maintenance, high-quality rotor-stator assemblies can last 6–12 months in continuous operation, depending on the abrasiveness of the plaster slurry and operational pressure. Regular inspection and timely replacement of worn parts extend the lifespan of the entire pump system.

**What maintenance is required for the fixed shaft and rotor-stator assembly?**

Routine cleaning to remove plaster buildup is critical. Inspect the rotor-stator gap monthly for wear and ensure the fixed shaft remains aligned to prevent vibration. Lubricate bearings and seals as specified by the manufacturer to minimize friction and avoid leaks.

**Are these parts compatible with different brands of plaster machines?**

Yes, factory-quality rotor-stator pump parts are designed to meet industry-standard dimensions and specifications. However, always verify compatibility by cross-checking part numbers, shaft diameter, length, and thread type with your machine’s requirements before purchasing.

**What are the signs of a failing rotor-stator or fixed shaft?**

Common indicators include reduced pumping efficiency, irregular noise or vibrations, leakage around the shaft seal, and visible wear or cracks on the rotor or stator surfaces. Immediate replacement is recommended to avoid unplanned downtime or damage to the pump housing.

(Factory quality rotor stator pump parts plaster machine screw pump rotor fixed shaft)

REQUEST A QUOTE

RELATED PRODUCTS

High Precision 5 Axis Copper Brass Shafts For Precise Cnc Machining Service Auto Turning Part Car Parts Cnc Processing Product

Comprehensive Production All Types Of Shafts Precisely Engineered Alloy Aluminum Stainless Steel Long Linear Shafts Suitable

SCM440 38XM 1.7225 Heavy Industry Large Forging Shaft For Big Machinery Equipment

Custom Long Crank shaft Drive Forging Large Eccentric shaft

Universal Joint U-joint Cross Bearing 5-134X universal steering shaft joint