PRODUCT PARAMETERS

Description

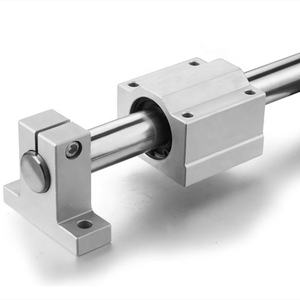

Introduction to Good quality anodize bicycle drive shaft with non-standard size

Good quality anodize bicycle drive shaft with non-standard size are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Good quality anodize bicycle drive shaft with non-standard size

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Good quality anodize bicycle drive shaft with non-standard size)

Specification of Good quality anodize bicycle drive shaft with non-standard size

Anodizing is a process used to give。One common requirement for anodized bicycles is that the drive shaft must meet specific specifications in terms of size and material.

The drive shaft is the pivot point for the rear wheel, and its size is critical for proper functioning of the bike. It needs to be large enough to accommodate the chain and bolts needed for pedaling, while also being small enough to fit comfortably in the handlebars. In general, the drive shaft should have a length of at least 45mm to ensure that it can fully swing back when pedaling, but no more than 60mm to prevent binding.

In addition to size, the drive shaft material must also meet certain standards. Most modern bicycles use aluminum or steel as their primary material, but some models may also feature carbon fiber or titanium for improved durability and performance. The material used will affect the strength and weight of the drive shaft, as well as its cost and availability.

Overall, specifying good quality anodized bicycle drive shafts is important to ensure that your bike functions properly and lasts long. By following the specific requirements outlined above, you can ensure that your drive shaft meets the highest standards of quality and performance.

(Good quality anodize bicycle drive shaft with non-standard size)

Applications of Good quality anodize bicycle drive shaft with non-standard size

Good-quality anodize bicycle drive shafts are essential components for protecting your bike’s frame and gears from corrosion, wear, and damage. However, if you’re looking for a unique way to modify or customize the appearance of your ride, consider using a non-standard size drive shaft.

One option is to create a custom anodize finish that matches your desired color or pattern. With most anodizing processes, you can use a colorant that goes on smooth and evenly, making it easy to achieve the desired result. You may also want to choose a colorant that adheres well to your shaft, such as one that resists fading over time.

Another option is to use a different type of anodizing process, such as electrostatic or plasma anodizing. These processes involve passing an electric current through the anodized material to create a unique texture or pattern. This can be especially useful if you want to add a touch of personality to your ride.

If you’re not sure which anodizing process is right for you, it’s always best to consult with a professional. They can help you choose the best finish for your needs and provide guidance on how to apply it properly.

Overall, anodize bicycle drive shafts are an excellent investment for anyone who wants to protect their bike and add a unique touch of style. By using a non-standard size or an anodizing process, you can create a truly customized ride that reflects your personal taste and preferences. So why wait? Start experimenting today and find the perfect anodize finish for your bike!

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Good quality anodize bicycle drive shaft with non-standard size

1. What is the difference between anodized and painted bicycles? Anodizing is a chemical process that transforms metal components, such as wheels or frames, into blackened finish using a mixture of chemicals and heat. It creates a durable and long-lasting surface for the parts to form contact with the ground. Painted bicycles, on the other hand, have a clear coating applied to the metal frame to protect it from scratches and wear.

2. Can anodized bicycles be used for racing? Yes, anodized bicycles can be raced just like regular bicycles, although they may require some modifications to handle certain types of terrain or corners. For example, some bikes may need specialized hardware or adjustments to optimize their performance in high-speed races.

3. Are anodized bicycles more environmentally friendly than regular bicycles? Anodized bicycles produce significantly less waste than traditional bicycles when disposed of. This is because anodizing does not involve processes that can release harmful toxins into the air, making them safer and more sustainable to use. Additionally, the materials used to make anodized bikes are often recyclable, which reduces their overall environmental impact.

4. Is anodizing only available for aluminum bicycles? No, anodizing is also available for many other materials, including carbon fiber, titanium, and stainless steel. The specific options available will depend on the type of material being used.

5. How do I know if my bike’s drive shaft is an anodized one? To determine whether your bike’s drive shaft is an anodized one, you can check the manufacturer’s specifications or consult online resources. Look for information on the “Anodization” or “Non-Synthetic Finish” label on the shaft. If the label indicates that the shaft is an anodized option, then it is likely an anodized drive shaft. If the label does not indicate anything, it is possible that the shaft is made from a different material and therefore does not qualify as an anodized option.

(Good quality anodize bicycle drive shaft with non-standard size)

REQUEST A QUOTE

RELATED PRODUCTS

HXMT From China Oem Large Module Big Diameter Shrink Fit Cast Iron Shaft Double Helical Herringbone Bull Spur Gears

mahindra alfa auto rickshaw spare parts CCL FOR hummer parts H1 H2 hummer h3 cv joint ford transit CV AXLE DRIVE SHAFT 88982496

Factory Customizable OEM Drawing Products Elastic Coupling Cardan Drive Shaft Plum-Shaped Steel OEM Drawing Available

Custom Long Crank shaft Drive Forging Large Eccentric shaft

Large OEM Machining Forged 42CrMo High quality Grinding Long Metal forged steel spline shaft