PRODUCT PARAMETERS

Description

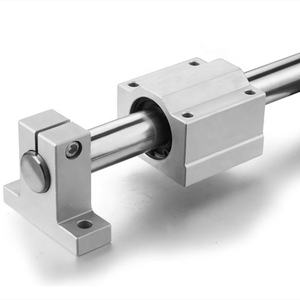

Introduction to Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear

Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear)

Specification of Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear

The Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear is a high-performance component designed for demanding industrial applications. Crafted from 4140 alloy steel, this shaft offers exceptional strength, durability, and resistance to wear, making it ideal for heavy-duty machinery and equipment. The material is heat-treated to enhance its mechanical properties, ensuring superior hardness and toughness, which are critical for withstanding high stress and load conditions.

The shaft features a large module design, which allows it to handle higher torque and power transmission requirements. It is precision-engineered to ensure accurate tooth profiles and tight tolerances, resulting in smooth and efficient operation. The helical or spur gear configuration provides versatility, catering to different application needs. Helical gears offer quieter operation and higher load capacity due to their angled teeth, while spur gears are known for their simplicity and efficiency in transmitting power.

The broaching process used in manufacturing ensures precise keyway dimensions and excellent surface finish, which are essential for seamless integration with other components. This precision reduces friction and wear, extending the lifespan of the shaft and the machinery it serves. The shaft is also designed to minimize backlash, ensuring reliable and consistent performance in high-speed and high-torque environments.

This product is suitable for a wide range of industries, including automotive, aerospace, construction, and heavy machinery. Its robust construction and precision engineering make it a reliable choice for applications such as gearboxes, transmissions, and power transmission systems. The 4140 steel composition provides excellent resistance to fatigue and impact, ensuring long-term reliability even under extreme operating conditions.

In summary, the Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear is a high-quality, durable, and versatile component designed to meet the rigorous demands of modern industrial applications. Its precision engineering, superior material properties, and adaptability make it an essential part of any high-performance machinery system.

(Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear)

Applications of Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear

The Applications of Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear are vast and critical across various industries, thanks to its exceptional strength, durability, and precision engineering. This high-performance component is crafted from 4140 steel, a chromium-molybdenum alloy known for its excellent toughness, wear resistance, and ability to withstand high stress and fatigue. The large module design ensures it can handle heavy-duty applications, making it ideal for industries that demand robust and reliable machinery.

In the automotive sector, this broaching shaft with helical or spur gears is widely used in transmission systems, differential assemblies, and powertrain components. Its precision engineering ensures smooth power transmission, reduced noise, and enhanced efficiency, which are essential for modern vehicles. The helical gear design, in particular, offers superior load distribution and quieter operation compared to traditional spur gears, making it a preferred choice for high-performance and luxury vehicles.

The aerospace industry also benefits significantly from this component. The 4140 steel’s high strength-to-weight ratio and resistance to extreme temperatures make it suitable for aircraft landing gear systems, engine components, and other critical applications where reliability and precision are non-negotiable. The helical gear configuration further enhances performance by providing smoother engagement and reduced vibration, which is crucial for maintaining the integrity of aerospace systems.

In heavy machinery and industrial equipment, this broaching shaft is employed in gearboxes, conveyor systems, and hydraulic machinery. Its ability to withstand heavy loads and harsh operating conditions ensures minimal downtime and extended service life, reducing maintenance costs and improving productivity. Additionally, the precision broaching process guarantees tight tolerances and superior surface finish, ensuring seamless integration with other components.

Overall, the Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear is a versatile and indispensable component in industries that require high-performance, durable, and precision-engineered solutions. Its unique combination of material properties and design features makes it a reliable choice for demanding applications, ensuring optimal performance and longevity.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear

The Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear is a high-performance component designed for demanding industrial applications. Here are five frequently asked questions about this product:

1. **What is the material used in this broaching shaft, and why is it significant?**

The shaft is made from 4140 steel, a high-strength alloy known for its excellent toughness, wear resistance, and durability. This material is ideal for heavy-duty applications, ensuring the shaft can withstand high stress, torque, and operational demands without compromising performance.

2. **What is the difference between helical and spur gears on this shaft?**

Helical gears are cut at an angle, providing smoother and quieter operation due to gradual tooth engagement. They are ideal for high-speed and high-load applications. Spur gears, on the other hand, have straight teeth and are simpler in design, making them suitable for moderate-speed applications. The choice depends on the specific requirements of your machinery.

3. **What is the significance of large module precision in this shaft?**

Large module precision refers to the high accuracy and larger tooth size of the gears, which enhances load-bearing capacity and reduces wear over time. This precision ensures optimal performance, minimal backlash, and extended service life, making it suitable for heavy industrial use.

4. **What industries commonly use this broaching shaft?**

This shaft is widely used in industries such as automotive, aerospace, construction, and heavy machinery. Its robust design and precision make it ideal for applications like gearboxes, power transmission systems, and industrial equipment requiring high torque and reliability.

5. **How does the broaching process enhance the shaft’s performance?**

Broaching is a machining process that creates precise keyways or splines on the shaft, ensuring a perfect fit with mating components. This process enhances the shaft’s strength, alignment, and load distribution, reducing the risk of failure and improving overall efficiency.

In summary, the Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear is a versatile, durable, and high-performance solution for industrial applications. Its material, precision, and design make it a reliable choice for demanding environments.

(Large Module Precision 4140 Steel Broaching Shaft with Helical/Spur Gear)

REQUEST A QUOTE

RELATED PRODUCTS

VNV radial 22320 ca mb cc self aligning spherical roller bearing of thrust roller shaft rodamiento de rodillos esfericos

SDS Auto Parts Discovery & Evoque 2.0T/3.0T 8AT Right Drive Shaft LR064251 Joint Transmission Shaft

Large OEM Machining Forged 42CrMo High quality Grinding Long Metal forged steel spline shaft

Stainless Steel Gear Shaft for Heavy Machinery High Rotational Speed Input/Output Shaft for Construction Industries

Universal Joint U-joint Cross Bearing 5-134X universal steering shaft joint