PRODUCT PARAMETERS

Description

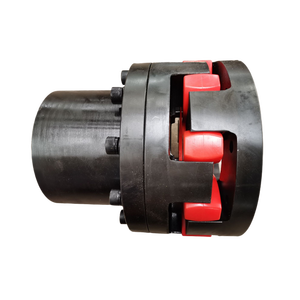

Introduction to Long axis customization Aluminum shaft customization Aluminum shaft processing small shaft processing

Long axis customization Aluminum shaft customization Aluminum shaft processing small shaft processing are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Long axis customization Aluminum shaft customization Aluminum shaft processing small shaft processing

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Long axis customization Aluminum shaft customization Aluminum shaft processing small shaft processing)

Specification of Long axis customization Aluminum shaft customization Aluminum shaft processing small shaft processing

Aluminum shafts are widely used in various industries for their lightweight, durable, and corrosion-resistant properties. However, the length of these shafts can vary depending on their specific application. In this article, we will discuss the specification of long-axis customization aluminum shafts.

The first step in specifying long-axis customization aluminum shafts is determining the required length. This can be done by taking into account factors such as the dimensions of the part being manufactured, the material to be used, and the desired finish. Once the length has been determined, it is then necessary to specify the diameter of the shaft. This is typically done using standard sizes or by customizing the diameter based on the unique requirements of the part being manufactured.

Once the length and diameter have been specified, the next step is to process the aluminum shaft. This involves shaping, forming, and finishing the shaft to meet the required specifications. The process may involve using various techniques such as lapping, drilling, etching, or CNC machining.

To ensure that the aluminum shaft meets the desired performance characteristics, it is important to consider factors such as strength, stiffness, and precision. This can be achieved through various processes such as heat treatment, surface treatments, or precision engineering.

In conclusion, specifying long-axis customization aluminum shafts requires careful consideration of several factors, including length, diameter, and processing methods. By carefully considering these specifications, manufacturers can produce high-quality aluminum shafts that meet the specific needs of their applications.

(Long axis customization Aluminum shaft customization Aluminum shaft processing small shaft processing)

Applications of Long axis customization Aluminum shaft customization Aluminum shaft processing small shaft processing

Long-axis customization, also known as, is a process in which the length of an aluminum shaft is tailored to meet specific requirements. This can include things like increasing or decreasing the length of the shaft, adding internal features or tolerances, or making changes to the shape and profile of the shaft.

One potential application of long-axis customization is in the manufacturing of small precision components such as gears, pulleys, and other parts with intricate geometries. By customizing the length of the shaft, manufacturers can produce parts that are more accurate and precise than traditional manufacturing methods.

Another possible use of long-axis customization is in the production of complex machines and equipment such as industrial machinery, aerospace engines, and even medical devices. For example, custom aluminum shafts can be used to manufacture specialized components that are designed for use in extreme environments, such as high-temperature applications or those subject to heavy loads.

In addition to its practical applications, long-axis customization can also have aesthetic benefits. Customized aluminum shafts can help to improve the overall appearance and functionality of machines and equipment, making them more visually appealing and easier to operate.

Overall, long-axis customization offers many opportunities for businesses looking to improve the performance and efficiency of their products. Whether you’re interested in manufacturing small precision components or producing complex machines and equipment, we can help you create customized aluminum shafts that meet your specific needs and requirements.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Long axis customization Aluminum shaft customization Aluminum shaft processing small shaft processing

1. What is aluminum shaft customization?

An aluminum shaft is customized by shaping it into specific profiles, sizes, and designs using specialized tools and machines. This process involves adding features such as chamfering, drilling, and machining to the shaft.

2. What are the benefits of aluminum shaft customization?

One of the key benefits of aluminum shaft customization is that it allows for greater precision and accuracy in applications where strong and durable materials are required. It also enables manufacturers to produce smaller, lighter, and more cost-effective components with fewer parts than traditional metal alloys.

3. Who can customize aluminum shafts?

Customization of aluminum shafts can be done by companies or individuals who specialize in casting, forging, or machining. Some common types of customizations include:

a) Castings: This involves making a shape or pattern on a blank aluminum bar, then molten aluminum is poured onto it to create the desired part.

b) Forging: This involves heating up a piece of aluminum until it flows under pressure, then it can be shaped or formed into a particular shape.

c) Machining: This involves cutting and shaping metal into intricate shapes and designs using high-powered machinery.

4. What makes aluminum shaft processing different from other materials?

Aluminum shaft processing is unique because it uses a combination of heat treatment, CNC (Computer Numerical Control) milling, and computer-aided design (CAD) software to produce precise, complex parts with minimal waste. These techniques enable manufacturers to achieve higher levels of quality and consistency than they could with traditional metal alloys.

5. Can I print aluminum shafts?

While printing aluminum shafts is not yet widely available, some manufacturers have started experimenting with this technology. The use of 3D printers to produce aluminum shafts offers a new level of customization and flexibility, but it remains a relatively niche option.

(Long axis customization Aluminum shaft customization Aluminum shaft processing small shaft processing)

REQUEST A QUOTE

RELATED PRODUCTS

Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining

High-strength Ship Propeller Shaft Alloy Ring Forgings 1.4418/X4CrNiMo16-5-1

Comprehensive Production All Types Of Shafts Precisely Engineered Alloy Aluminum Stainless Steel Long Linear Shafts Suitable

Custom Hollow Shaft Stepped Shafts CNC Machining Factory Turning Milling Chengshuo Hardware Machined

316 304 stainless steel rod long 2mm 8mm aluminum shaft pin 25mm 40mm threaded knurled shaft steel metal shaft