PRODUCT PARAMETERS

Description

Introduction to OEM custom CNC turning bearing shaft High precision stainless steel rotary shaft long linear steel shaft

OEM custom CNC turning bearing shaft High precision stainless steel rotary shaft long linear steel shaft are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of OEM custom CNC turning bearing shaft High precision stainless steel rotary shaft long linear steel shaft

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(OEM custom CNC turning bearing shaft High precision stainless steel rotary shaft long linear steel shaft)

Specification of OEM custom CNC turning bearing shaft High precision stainless steel rotary shaft long linear steel shaft

OEM Custom CNC Turning bearing shaft is designed for high precision applications, providing reliable performance in all environments. It features a series of concentric rotating holes that can be precisely milled to meet your specific requirements.

The shaft is made from high-quality stainless steel, ensuring durability and longevity under various conditions. The diameter of the shaft is adjustable to accommodate different materials, making it suitable for various applications such as automotive, aerospace, and medical devices.

The shaft is also equipped with a series of wear-resistant seals that prevent contamination and ensure optimal operation. The borehole is bored to the desired size using a drilling machine, followed by the insertion of the bearing into the shaft. The bearing is held securely in place using a locating pin, preventing backlash and ensuring smooth rotation.

To further enhance the accuracy and reliability of the bearing, the shaft is subjected to rigorous testing and quality control measures before being shipped out. This ensures that each part meets the highest standards for quality and performance.

In summary, the OEM Custom CNC Turning bearing shaft is an excellent choice for high-precision applications where stability, durability, and resistance to contamination are essential. With its adjustable borehole size, durable stainless steel construction, and precise machining capabilities, this bearing will provide consistent performance for years to come.

(OEM custom CNC turning bearing shaft High precision stainless steel rotary shaft long linear steel shaft)

Applications of OEM custom CNC turning bearing shaft High precision stainless steel rotary shaft long linear steel shaft

OEM Custom CNC Turning Bushings: Benefits and Advantages

One of the most critical components of any mechanical system is the bushing that supports the rotating parts. In the case of CNC turning, a high-precision bushing ensures precise rotational motion without or play. A customized CNC turning bushing is essential for applications where accuracy is paramount, such as in medical equipment, automotive machinery, and aerospace manufacturing.

Customized CNC turning bushings can be designed to meet specific specifications, such as length, width, thickness, and thread count. This allows manufacturers to optimize their machines for specific tasks, thereby improving productivity and reducing downtime. Additionally, customized bushings can help to minimize material waste by using less material than standard bushings.

One of the main benefits of using a customized CNC turning bushing is the improved quality of the finished product. Because each bushing is designed specifically for each application, it offers greater resistance to wear and tear, which reduces maintenance costs and prolongs the lifespan of the part. Furthermore, customized bushings can help to reduce stress on moving parts, leading to fewer breakdowns and longer service intervals.

Another advantage of using a customized CNC turning bushing is the ability to save time and money compared to purchasing pre-made bushings. By taking the time to design and produce the custom bushing, manufacturers can ensure that it meets the specific requirements of their application, while also minimizing material waste and reducing production costs.

In conclusion, CNC turning bushes are an essential component of any machine that requires precision rotational motion. By using a customized CNC turning bushing, manufacturers can improve the quality of their products, reduce downtime, and save time and money compared to purchasing pre-made bushings. Whether you are a manufacturer of medical equipment, automotive machinery, or aerospace manufacturing, investing in customized CNC turning bushes is likely to pay off in the long run.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of OEM custom CNC turning bearing shaft High precision stainless steel rotary shaft long linear steel shaft

1. What is the difference between an OEM (Original Equipment Manufacturer) custom CNC turning bearing shaft and a high precision stainless steel rotary shaft? The main difference lies in their material, precision, and durability. An OEM custom CNC turning bearing shaft is made specifically for the client’s specific requirements, ensuring that it meets their exact specifications and performs at peak efficiency. On the other hand, a high precision stainless steel rotary shaft is made from high-quality materials such as 316L stainless steel, which offers excellent corrosion resistance, and is known for its strength, durability, and ability to withstand heavy loads.

2. Are there any additional features or benefits that differentiate the high precision stainless steel rotary shaft from an OEM custom CNC turning bearing shaft? One of the most notable differences is the level of precision and accuracy that can be achieved with each type of shaft. A high precision stainless steel rotary shaft is designed to provide precise movement within a manufacturing process, resulting in fewer errors and increased efficiency. Additionally, this type of shaft often has features such as bushings, ball bearings, and grease fittings, which can further enhance its performance and reduce wear on moving parts.

3. Can I order a custom CNC turning bearing shaft without specifying the size or shape of the shaft? Yes, you can place an order for a custom CNC turning bearing shaft with no specific measurements. Our team will work closely with you to understand your requirements and provide recommendations based on the specific needs of your application. We also offer customized shafts in different shapes, sizes, and configurations to ensure that they meet your unique requirements.

4. How does the cost of a high precision stainless steel rotary shaft compare to an OEM custom CNC turning bearing shaft? The cost of a high precision stainless steel rotary shaft may vary depending on several factors such as the complexity of the shaft design, the material used, and the production quantity. However, compared to an OEM custom CNC turning bearing shaft, our high precision stainless steel rotary shaft may have higher upfront costs due to the use of high-quality materials and advanced technologies. However, in the long run, the benefits of a custom shaft, including improved precision, reduced maintenance costs, and increased productivity, may outweigh the initial investment. Additionally, our team can work with you to optimize the design and manufacturing process to minimize the overall cost of the shaft.

5. Can I request samples of a high precision stainless steel rotary shaft before placing an order? Yes, we do provide samples of our high precision stainless steel rotary shaft for free upon request. Our team will carefully examine the sample and provide you with detailed information about its dimensions, features, and performance characteristics. This allows you to get a better understanding of how the shaft will perform in your application and make an informed decision before committing to a larger purchase order.

(OEM custom CNC turning bearing shaft High precision stainless steel rotary shaft long linear steel shaft)

REQUEST A QUOTE

RELATED PRODUCTS

Comprehensive Production All Types Of Shafts Precisely Engineered Alloy Aluminum Stainless Steel Long Linear Shafts Suitable

Best Quality Low Top Grade Darts Stems Accessories Flights Nylon Dart Shafts

Right Hand Rear OEM 42311-60190 Shaft Drive Axle For Car FZJ HDJ HZJ VDJ 76 78 79

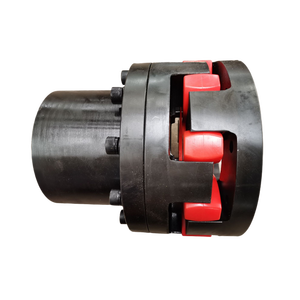

Z5 Assembly Power Transmission Parts with Locking Elements Shaft for Secure Shaft Locking Device

Customized crankshaft for engine Forging Steel OEM crankshaft professional manufacture, crankshaft