Shaft

Custom Metal Processing Service CNC Machine Spare Parts 5 Axis Precision Machining Parts Worm Gear Shaft

Good quality anodize bicycle drive shaft with non-standard size

Custom Cnc Hrc61~65 8Mm Motor Shaft S304 S316 Stainless Steel Motor Armature Shaft

Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining

Customized crankshaft for engine Forging Steel OEM crankshaft professional manufacture, crankshaft

High Quality Whole Caliburn SUP Moulded Shaft And Flight Multiple Colors Accessories For Tungsten Darts Three Sizes

Custom Logo Cnc High Precision Ac Motor Shaft Sus304 Sus316L Sus410 Stainless Steel Motor Shaft

High-strength Ship Propeller Shaft Alloy Ring Forgings 1.4418/X4CrNiMo16-5-1

Customized crankshaft for engine Forging Steel crankshaft professional manufacture crankshaft

316 304 stainless steel rod long 2mm 8mm aluminum shaft pin 25mm 40mm threaded knurled shaft steel metal shaft

Custom Precision Slender Stainless Steel Shaft CNC Turning Machining Service Rapid Prototyping Drilling Wire EDM Micro Machining

DIN6885AB Stainless Steel 304 316 Double Round Square Ends Flat Parallel Machine Shaft Key

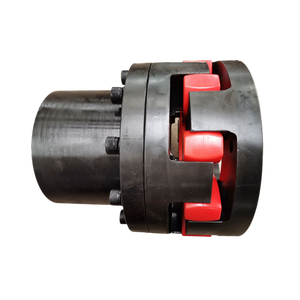

Overview of Mine Heavy Machinery Shaft

Mine Heavy Machinery Shafts are critical components used in mining equipment to transmit mechanical power and support rotating parts. These shafts are typically used in high-load, high-torque environments and require extreme strength and durability to cope with harsh operating conditions. They are designed to ensure the stability and reliability of machinery and equipment in extreme environments.

Features of Mine Heavy Machinery Shaft

High-Strength Materials: Typically made from high-strength alloy steels or specialty alloys to withstand high mechanical stresses.

Fatigue resistance: Special treatments (such as heat treatment or surface hardening) are applied to improve fatigue resistance and extend service life.

Precision Manufacturing: High-precision machining ensures a perfect match between the shaft bea, rings and other mating parts, reducing vibration and wear.

Anti-corrosion treatment: Surfaces are often treated with anti-corrosion therapies, such as zinc plating or coatings, to resist the erosion of moisture and corrosive substances.

Customized design: This can be customized according to the specific needs of different mechanical equipment, including size, shape and connection methods.

Specifications of Shaft

| Specification | Description |

|---|---|

| Type | Straight Shaft, Stepped Shaft, Hollow Shaft, Flexible Shaft |

| Material | Steel (e.g., Carbon Steel, Alloy Steel), Stainless Steel, Aluminum |

| Diameter | 5mm to 300mm (Customizable) |

| Length | 10mm to 2000mm (Customizable) |

| Surface Treatment | Polishing, Black Oxide, Zinc Plating, Chrome Plating, Heat Treatment |

| Tolerance | IT6 to IT8 (ISO Standard), Customizable based on requirement |

| Hardness | Varies by material and treatment, typically 20-60 HRC |

| Application | Automotive, Aerospace, Industrial Machinery, Consumer Appliances, etc. |

| Finish | Smooth or textured, based on application needs |

| Weight | Depends on material, diameter, and length |

| Certifications | ISO 9001, ISO/TS 16949, SAE, ASTM |

| Packaging | Individually wrapped, boxed in batches, or palletized based on customer's request |

Application Scenarios of Mine Heavy Machinery Shaft

Excavators: Used to drive the digging arm and other moving parts to realize efficient digging operations.

Bulldozer: Supports lifting and tilting movements of the bulldozer plate to help level the ground.

Loaders: Drive the lifting and tilting operations of buckets to facilitate material handling.

Drilling rig: Supports the rotation of the drill bit to provide stable drilling capacity for ore exploration and mining.

Conveyor Belt Systems: Drive drums for long-distance transportation of ore and waste materials.

Company Introduction

Welcome to Port of Machinery, a leading foreign trade company specializing in the sales of high-quality shafts worldwide. With over two decades of experience, we offer a wide range of shafts tailored to meet diverse industrial needs, ensuring superior performance and reliability in every product. Our commitment to excellence has made us a trusted name in the international market.

5 Frequently Asked Questions (FAQs) of Mine Heavy Machinery Shaft

What materials are mine heavy machinery shafts usually made of?

Mainly stre,ngth alloy steel or other specialty alloys are used, which have excellent strength and wear resistance.

How do I maintain my Mine Heavy Machinery Shaft?

Regularly check the condition of the shaft to ensure good lubrication and avoid excessive wear. Any damage found should be repaired or replaced promptly.

Are shafts repairable?

Minor damage can be repaired by welding or machining, but for severe damage, it is recommended to replace the shaft with a new one to ensure safety and performance.

Are there customized shafts for specific equipment?

Yes, many manufacturers offer customized solutions for specific needs to meet the unique requirements of different equipment.

What is the life expectancy of shafts for heavy machinery in mining?

Life expectancy depends on usage and quality of maintenance and can typically last many years or even a decade with proper maintenance.