PRODUCT PARAMETERS

Description

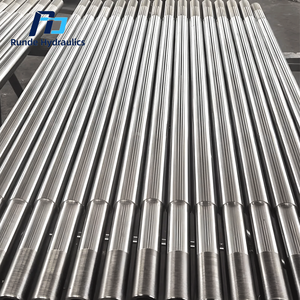

Introduction to Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing

Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing)

Specification of Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing

The solid surface 304 stainless steel grinding round shaft, rod, and for mechanical manufacturing is an essential component in the manufacturing process of precision engineering components. These products have become increasingly popular due to their durability, corrosion resistance, and ability to handle high loads.

The grinding round shaft features a diameter of 30mm and a length of 1m. It has been manufactured using high-quality materials that ensure maximum strength and longevity. The shaft is made from 304 stainless steel, which is known for its durability and resistance to corrosion. This material ensures that the grinding rod will not rust or corrode, even under harsh conditions.

The grinding round rod is designed to be used in conjunction with the grinding round shaft. It features a diameter of 25mm and is longer than the grinding round shaft. The rod has been manufactured using high-strength materials that provide additional rigidity and support for the grinding operation. The rod is also made from 304 stainless steel, which offers the same level of corrosion resistance as the grinding round shaft.

In conclusion, the solid surface 304 stainless steel grinding round shaft, rod, and for mechanical manufacturing are essential components in the manufacturing process of precision engineering components. They are durable, resistant to corrosion, and offer exceptional performance in handling high loads. With these products, manufacturers can produce high-quality components quickly and efficiently, leading to increased productivity and reduced costs.

(Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing)

Applications of Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing

Solid surface 304 stainless steel grinding round shaft and rod are essential tools for mechanical manufacturing in various industries, such as automotive, aerospace, and medical equipment. These products are made from high-quality materials that provide optimal performance, durability, and resistance to corrosion.

The grinding round shaft is used in manufacturing processes where precision grinding and honing are required. It has a unique feature of being able to match the tolerance requirements of other parts, which makes it an ideal tool for precise mechanical components. The round rod is used in conjunction with the grinding round shaft to create advanced mechanical systems that require complex geometries. This includes CNC machines, lathes, milling machines, and robotic arms.

One of the main advantages of using solid surface 304 stainless steel grinding round shaft and rod is their excellent corrosion resistance. Unlike other metals, 304 stainless steel is resistant to corrosion caused by moisture, saltwater, and acidic environments. This makes it suitable for use in harsh and working conditions, including marine applications and food processing facilities.

Another advantage of these products is their ease of maintenance and cleaning. They are made from durable materials that can withstand wear and tear, making them easy to clean and maintain. The surface of the material is notched, which makes it easy to remove dirt and debris without damaging the surface.

In conclusion, solid surface 304 stainless steel grinding round shaft and rod are essential tools for mechanical manufacturing in various industries. Their unique features, such as high-quality materials, excellent corrosion resistance, and ease of maintenance and cleaning make them an ideal choice for professionals in manufacturing processes. By choosing these products, you can ensure that your mechanical components meet the highest standards of quality and performance.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing

1. What is Solid Surface 304 stainless steel grinding round shaft and rod for mechanical manufacturing?

Solid Surface 304 stainless steel is a type of high-strength, corrosion-resistant stainless steel that is known for its durability and ease of use in various applications. Its resistance to corrosion makes it an ideal material for use in industrial equipment and machinery.

A grinding round shaft and rod are two key components used in the production process of mechanical manufacturing. A grinding round shaft is a round metal rod that is used to grind surfaces, while a grinding rod is a cylindrical tool that is used to grind circular objects. Both components play important roles in ensuring that the final product meets the desired specifications.

2. How do I select the right size for a grinding round shaft and rod?

When selecting a grinding round shaft and rod, you will need to consider several factors, including the size of the object being ground, the size of the machine or equipment being used, and the requirements of the end product. It is important to choose a rod and shaft that is compatible with your machine and that has enough leverage to effectively grind the surface.

To determine the appropriate size of the rod and shaft, you can consult industry standards and guidelines, or ask the manufacturer for recommendations. Alternatively, you may need to perform some experimentation to find the optimal size for your specific application.

3. What are the benefits of using solid surface 304 stainless steel grinding round shaft and rod?

One of the main benefits of using solid surface 304 stainless steel grinding round shaft and rod is their durability and resistance to corrosion. Because solid surface 304 stainless steel is made from high-strength stainless steel, it is resistant to the effects of moisture, chemicals, and other environmental factors that can cause corrosion over time. This means that you can rely on your equipment to operate effectively for many years without needing to replace parts or invest in additional maintenance.

Another benefit of using solid surface 304 stainless steel grinding round shaft and rod is their ease of cleaning and maintenance. Solid surface 304 stainless steel is non-porous, which means that it does not trap dirt or debris. As a result, it requires less maintenance than many other materials, which can save you time and money in the long run.

4. Can I use solid surface 304 stainless steel grinding round shaft and rod in both wet and dry environments?

Yes, solid surface 304 stainless steel grinding round shaft and rod can be used in both wet and dry environments. Because they are made from high-strength stainless steel, they are able to withstand exposure to water, oils, and other liquids without losing their strength or integrity. They are also resistant to exposure to high temperatures, so they can be used in a variety of applications where heat needs to be removed from the surface.

However, it is important to note that the performance of solid surface 304 stainless steel grinding round shaft and rod may vary depending on the conditions under which it is used. For example, if the material is exposed to extreme temperatures, it may lose some of its strength and durability over time. Therefore, it is important to carefully consider the operating conditions and take appropriate measures to ensure that your equipment remains in good working condition.

5. Are there any safety precautions that I should follow when using solid surface 304 stainless steel grinding round shaft and rod?

Yes, there are several safety precautions that you should follow when using solid surface 304 stainless steel grinding round shaft and rod. One of the most important safety considerations is proper handling of the equipment. This includes wearing protective gear such as gloves and safety glasses, and following all relevant safety procedures and guidelines.

It is also important to ensure that the grinding medium being used is properly cleaned and filtered before use. This can help prevent contamination of the final product and reduce the risk of injury.

Finally, it is important to regularly inspect and maintain your equipment to identify any potential problems or hazards. By taking proactive steps to address these issues, you can help ensure that your equipment operates safely and efficiently.

(Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Long Crank shaft Drive Forging Large Eccentric shaft

Custom Hollow Shaft Stepped Shafts CNC Machining Factory Turning Milling Chengshuo Hardware Machined

SDS Drive Shafts 2201010W02 CS35 1.6L 5MT Left Half Shaft For Changan

201 303 430 317 329 347 630 416 410 420 904l 316l 310s 2507 Round Stainless Steel Shaft 316 304 Stainless Steel Bar Rod

Chinese Cnc High Hardness 6Mm Motor Shaft S304 S316 S410 Stainless Steel Motor Adapter Shaft