PRODUCT PARAMETERS

Description

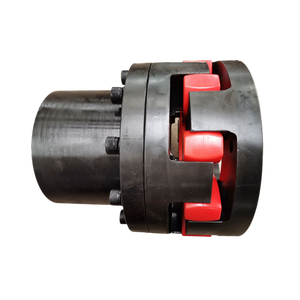

Introduction to Stainless Steel Gear Shaft for Heavy Machinery High Rotational Speed Input/Output Shaft for Construction Industries

Stainless Steel Gear Shaft for Heavy Machinery High Rotational Speed Input/Output Shaft for Construction Industries are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Stainless Steel Gear Shaft for Heavy Machinery High Rotational Speed Input/Output Shaft for Construction Industries

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Stainless Steel Gear Shaft for Heavy Machinery High Rotational Speed Input/Output Shaft for Construction Industries)

Specification of Stainless Steel Gear Shaft for Heavy Machinery High Rotational Speed Input/Output Shaft for Construction Industries

Stainless steel gears are commonly used in heavy machinery applications due to their durability and resistance to corrosion. One type of gear that is widely used in construction industries is the high rotational speed input/output shaft.

These shafts typically consist of a bearing that holds a gear inside, along with a housing made from stainless steel. The housing provides protection against corrosion and wear and tear caused by the high rotational speed of the gear. The bearing is typically made from a material that can withstand high temperatures and pressures, such as cast iron or steel.

The output shaft is what is connected to the rest of the machine. It is designed to move the mechanical components required to complete a task. The shaft may be made from a variety of materials, including carbon steel or titanium, depending on the specific application.

One key feature of stainless steel gears is their resistance to corrosion. This means that they are resistant to the formation of rust and other harmful substances that can damage the gear over time. In addition, stainless steel gears are often designed to be flexible, which allows them to handle different loads and speeds without breaking or wearing out.

Overall, stainless steel gears are an excellent choice for high rotational speed input/output shafts in construction industries. They offer superior durability, resistance to corrosion, and flexibility, making them a reliable and effective component for many different applications.

(Stainless Steel Gear Shaft for Heavy Machinery High Rotational Speed Input/Output Shaft for Construction Industries)

Applications of Stainless Steel Gear Shaft for Heavy Machinery High Rotational Speed Input/Output Shaft for Construction Industries

Stainless steel gear shafts are widely used in heavy machinery, particularly in construction industries. They provide robust and durable performance, even at high rotational speeds. This is due to their excellent corrosion resistance, which allows them to withstand harsh environments.

One of the primary applications of stainless steel gear shafts is in the input/output (I/O) system of heavy machinery. These shafts are often used as drives or idles that connect the output of one machine to the input of another. The use of stainless steel gears ensures that the shafts can handle significant loads and temperatures without degrading or breaking under stress.

Another application of stainless steel gear shafts in construction industries is in the construction equipment itself. For example, there are many excavators, track loaders, and excavator tracks that are equipped with stainless steel gears. These gears ensure that the equipment can move efficiently and smoothly over different types of terrain, making them ideal for construction projects.

In addition to their industrial uses, stainless steel gear shafts also have practical benefits. They are lightweight, making them easier to transport and install, and they are resistant to corrosion, which means that they will last longer than other materials. This makes them an attractive choice for companies that need to maintain their equipment for long periods of time.

Overall, stainless steel gear shafts are a versatile and reliable solution for heavy machinery and construction industry applications. Their durability, corrosion resistance, and ease of use make them an ideal choice for companies looking to improve the efficiency and safety of their operations.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Stainless Steel Gear Shaft for Heavy Machinery High Rotational Speed Input/Output Shaft for Construction Industries

1. What is stainless steel gear shaft?

Stainless steel gear shaft is a type of shaft made from high-strength, corrosion-resistant materials such as stainless steel. It is commonly used in heavy machinery applications where rotating devices require high speed and torque input.

2. How does stainless steel gear shaft perform?

Stainless steel gears are known for their durability, resistance to corrosion, and ability to maintain optimal performance under high rotational speeds. They can handle large loads, and are easy to maintain.

3. Are there any disadvantages to using stainless steel gear shafts?

One potential disadvantage of stainless steel gear shafts is that they may be more expensive than other types of shafts. Additionally, they may not be as flexible or lightweight as other materials.

4. Can stainless steel gears withstand extreme temperatures?

Yes, stainless steel gears are resistant to extreme temperatures, making them suitable for use in industrial settings where heat or moisture may cause damage to other types of shafts.

5. Can stainless steel gears be customized for specific applications?

Yes, stainless steel gears can be customized to meet the specific needs of a particular application. This may include changing the size or shape of the shaft, adding or removing components, or changing the material used.

(Stainless Steel Gear Shaft for Heavy Machinery High Rotational Speed Input/Output Shaft for Construction Industries)

REQUEST A QUOTE

RELATED PRODUCTS

Bus Spare Parts OEM Axle Drive Shaft Custom Transmission Driver Shafts for Higer Kinglong Zhongtong Bus

Professional customization of high-strength 316 stainless steel double-sided chamfered high-quality positioning shaft

Solid Surface 304 Stainless Steel Grinding Round shaft Round Rod For Mechanical Manufacturing

Hardware processing Shaft machining Mass Production Fabrication CNC Service Custom Made Precision parts machining

Custom Cnc Hrc61~65 8Mm Motor Shaft S304 S316 Stainless Steel Motor Armature Shaft