PRODUCT PARAMETERS

Description

Introduction to TOW SHAFTS WITH POWER HEAD, DRILL ROD AND DRILL HEAD

TOW SHAFTS WITH POWER HEAD, DRILL ROD AND DRILL HEAD are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of TOW SHAFTS WITH POWER HEAD, DRILL ROD AND DRILL HEAD

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(TOW SHAFTS WITH POWER HEAD, DRILL ROD AND DRILL HEAD)

Specification of TOW SHAFTS WITH POWER HEAD, DRILL ROD AND DRILL HEAD

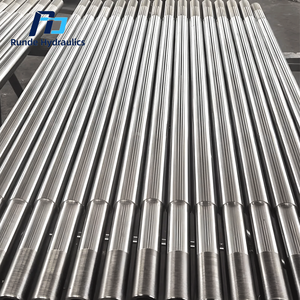

The TOW Shafts with Power Head, Drill Pole, and Drill Head develop a durable drilling system created for performance and longevity popular applications. The TOW shafts are created from high-strength alloy steel, heat-treated for enhanced wear resistance and torque ability. Offered in diameters varying from 50mm to 150mm and sizes of 1.5 m to 6m, these shafts feature precision-machined splines for smooth power transmission. The modular design permits simple combining for extended reach. The power head provides a maximum torque output of 5,000 Nm, powered by a hydraulic or electric motor (15– 30 kW), with variable speed control (0– 150 RPM) to adapt to differing ground problems. It consists of overload security and an incorporated air conditioning system to prevent getting too hot throughout long term procedure. The drill rod, made from smooth carbon steel with anti-corrosion finishing, is available in 1m or 1.5 m areas with global string connections (API requirement) for quick setting up. Its hexagonal or rounded profile makes sure optimum pressure transfer, compatible with the majority of boring gears. The drill head choices include auger, ruby core, or tricone bits, customized for soil, rock, or combined developments. Reducing sizes vary from 100mm to 300mm, with carbide-tipped teeth or PDC cutters for extensive life span. The system runs in temperatures from -20 ° C to 50 ° C and is ranked for midsts approximately 150m, relying on geology. Safety features include anti-vibration takes care of, emergency situation quit controls, and enhanced guards around turning components. Weighing roughly 250– 400kg (depending upon arrangement), the configuration is portable and compatible with skid-steer loaders or excavators. Adjustable options include flange adapters, extended shafts, or specialized finishings for abrasive atmospheres. Suitable for construction, mining, geothermal, and environmental exploration, this system focuses on precision, resilience, and customer security.

(TOW SHAFTS WITH POWER HEAD, DRILL ROD AND DRILL HEAD)

Applications of TOW SHAFTS WITH POWER HEAD, DRILL ROD AND DRILL HEAD

The TOW Shafts with Power Head, Drill Pole, and Drill Head develop a robust exploration system made for precision and effectiveness throughout diverse markets. These elements work synergistically to supply high-performance drilling in challenging environments. The power head creates rotational force, transmitted via the drill rod to the drill head, which passes through different materials. Here are key applications:

** Construction & Facilities: ** Ideal for foundation work, consisting of piling and securing, this system drills via dirt, rock, and concrete. It supports the installment of micropiles and ground supports for maintaining structures like bridges and maintaining wall surfaces. The modular style enables quick adjustment to various drill head kinds, improving versatility.

** Mining & Exploration: ** Made use of for mineral exploration and core tasting, the drill head’s resilience makes certain reliable infiltration into acid rock. The system’s mobility makes it possible for deployment in remote mining websites, while the power head’s adjustable torque maximizes performance throughout varying geological conditions.

** Geothermal Power: ** Facilitates the installation of geothermal warmth exchange systems by drilling upright or angled boreholes. The drill rod’s size and the power head’s RPM control make it possible for precise boring midsts, vital for maximizing thermal transfer performance.

** Agriculture & Water Wells: ** Drills irrigation wells and water boreholes in rural or off-grid areas. The system’s lightweight design and ease of setting up make it appropriate for small farming, providing trustworthy accessibility to groundwater.

** Environmental Tracking: ** Deployed for dirt tasting and setting up monitoring wells to examine contamination degrees. The drill head’s marginal disruption maintains example stability, while the power head’s low-noise procedure reduces ecological impact.

** Oil & Gas: ** Sustains exploratory boring in superficial reserves and well maintenance jobs. The corrosion-resistant products hold up against rough problems, making sure longevity in offshore or high-salinity environments.

Trick advantages consist of flexibility to diverse surfaces, minimized downtime due to quick part swaps, and improved safety and security with ergonomic controls. Built for toughness, the system operates effectively in extreme temperature levels and rough problems, supplying an affordable service for sectors requiring reliability and accuracy. Whether for urban advancement, resource extraction, or ecological jobs, this boring system provides unrivaled performance and operational versatility.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of TOW SHAFTS WITH POWER HEAD, DRILL ROD AND DRILL HEAD

What is the primary application of a tow shaft with power head, drill rod, and drill head?

These components are designed for heavy-duty drilling and excavation tasks in construction, mining, and agricultural projects. The power head generates rotational force, transmitted via the tow shaft to the drill rod and drill head, enabling efficient digging through soil, rock, or other tough materials. Common uses include foundation drilling, well drilling, and installing fence posts or geothermal systems.

How do I maintain the tow shaft and drill components for longevity?

Regular lubrication of the tow shaft’s joints and bearings is critical to reduce friction and wear. Inspect drill rods and heads after each use for cracks, bends, or blunt edges. Clean off debris and store components in a dry environment to prevent rust. Replace damaged parts immediately to avoid operational hazards and ensure smooth performance during drilling operations.

Are drill rods and heads compatible with different power head models?

Compatibility depends on the thread type, diameter, and torque specifications of the power head and drill components. Most systems adhere to standardized sizing, but always verify manufacturer guidelines before pairing. Universal adapters are available for mixing brands, though using matched components from the same manufacturer is recommended to ensure optimal performance and safety.

What safety precautions should I follow when operating this equipment?

Always wear protective gear like gloves, goggles, and steel-toe boots. Secure the power head and tow shaft firmly to the drilling machine to prevent dislodging. Avoid loose clothing near rotating parts. Conduct a pre-operation check for loose bolts, hydraulic leaks, or damaged parts. Never exceed the recommended drilling depth or load capacity specified in the user manual.

What causes excessive vibration or overheating during drilling?

Vibration often results from misaligned drill rods, uneven terrain, or a worn-out drill head. Overheating may stem from insufficient lubrication, overloading the power head, or continuous use without cooling intervals. Stop operation immediately if either occurs. Check alignment, lubricate components, reduce drilling speed, and allow the system to cool. Persistent issues may indicate mechanical faults requiring professional inspection.

(TOW SHAFTS WITH POWER HEAD, DRILL ROD AND DRILL HEAD)

REQUEST A QUOTE

RELATED PRODUCTS

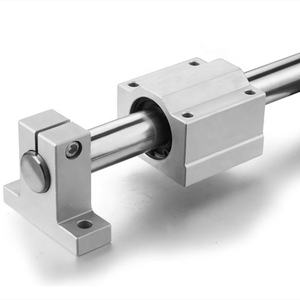

High Precision Linear Hollow shaft 3mm 55mm 60mm 70mm 80mm To 150mm Stainless Steel Chromed Hardened Linear Bearing Steel Shaft

SDS Drive Shafts 2201010W02 CS35 1.6L 5MT Left Half Shaft For Changan

Lower Telescopic Aluminium Telescopic Aluminium Linear Guide Rail Shaft for Water Pipe Plumbing

Shaft Assy Front Right For X-TRAIL Qashqai (J11) 2WD Cars 39100-4EF3C 391004EF3C

Brass Titanium Alloy Precision Cnc Parts Computer Gong Parts Motor Shaft Spindle Shafts Rotor Shaft